Aim high

Autonomous Forklift

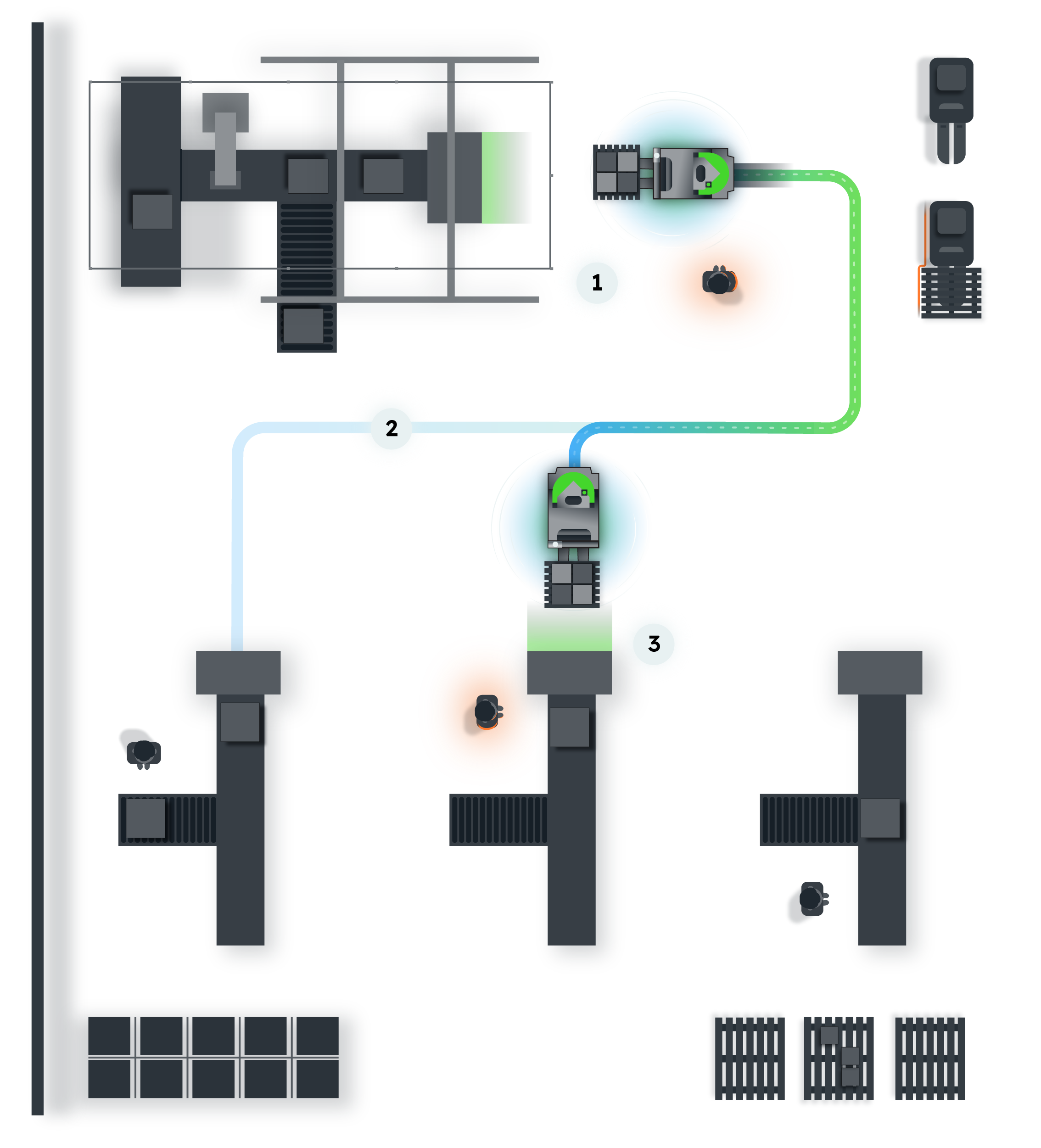

Meet the AFL

Built for dynamic, real-world environments, the AFL seamlessly handles vertical lifts, tight spaces, and mixed-traffic zones — all while boosting throughput and freeing up your workforce for higher-value tasks.

About Vecna AFL

A forklift for all seasons

Vecna AFL is a versatile driverless automated forklift that can move a wide range of payloads and pallet types. From ground-to-ground workflows to conveyer belt and riser lifts, Vecna AFL is our the all-around workhorse for your warehouse.

60 inch lift height

Blazing fast

6.7 mph top speed

Clean hand off

15’6 ft right angle stack

Squeezes thru

9 ft aisles at max speed

Features and Functionality

Up, up and away

Lift Higher, Transport More

Reaches up to 60″ height, with a payload of up to 3000 lbs

Versatile Pallet Handling

Handles a wide range of pallet payloads, from empty to full

Integrated Handoffs

Lifts to and from conveyors, wrappers, and more

Operate in Narrow Aisles

Navigates at top speed within 9′ aisles

Intuitive Interfaces

Assigns tasks using remote user interfaces

LPN Scanning

Scans pallet barcodes and send updates to your WMS

ANSI B56.5 Compliant

Keeps your employees, equipment and goods safe.

Opportunistic Charging

Runs 24/7 using manual opportunistic charging

Optimize your warehouse workflows

Case Study · Warehousing

Private global candy company moves 1500 per day at 80 cents per move

Let’s go

Optimize your critical workflows right now

Have questions about what Vecna can do for you? Tell us about yourself, and an automation expert will be in touch shortly.

Thank you for getting in touch

We aim to respond to all messages within 1-2 business days.

In the meantime you might be interested in some of these resources.