Pulls a ton, and more

Co-bot Pallet Jack

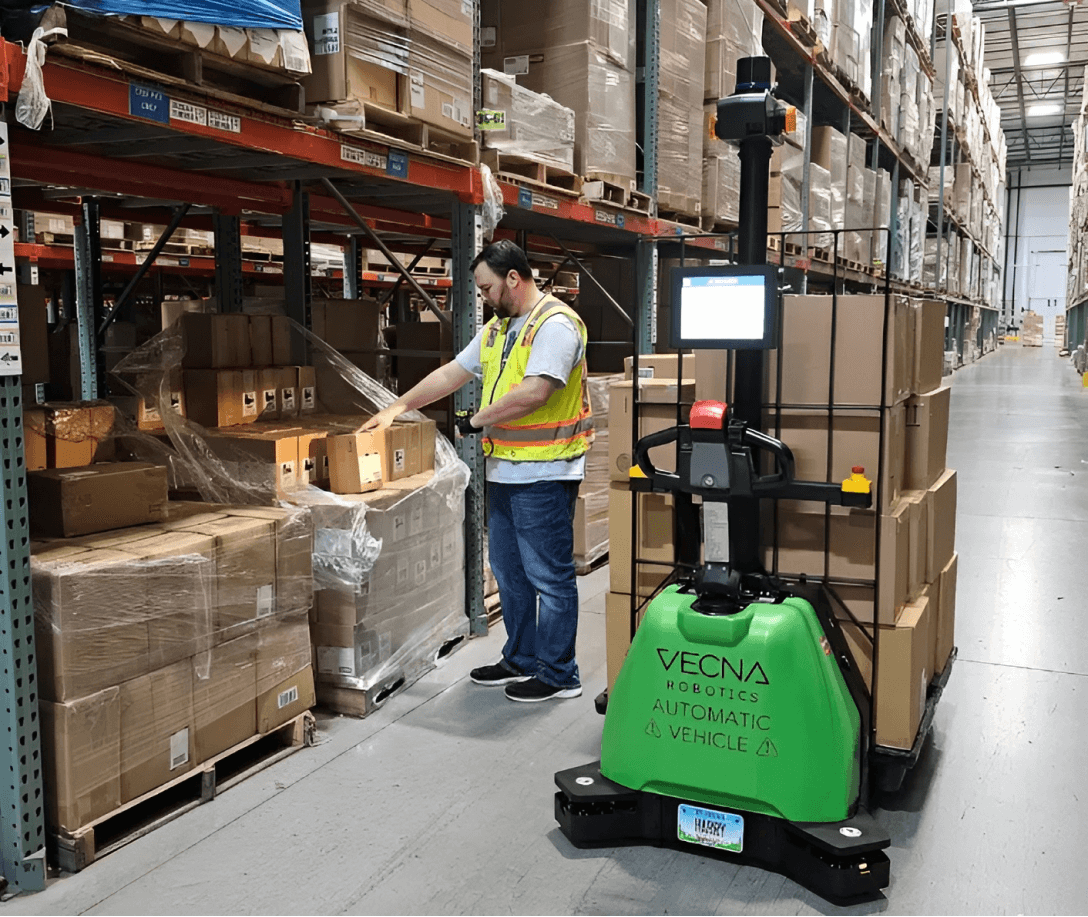

Meet the CPJ

Built to navigate tight spaces and automate short-distance transport, the CPJ handles repetitive, non-value add tasks in case picking and point-to-point workflows. Boost throughput, improve worker well-being and keep operations moving efficiently.

About Vecna CPJ

Improve existing worker throughput by up to 45%

Designed for nimble movement in tight spaces, the CPJ is optimized for replenishment, as well as for microworkflows such as waste/dunnage retrieval, empty pallet, tote/cart consolidation, pick-to-packout, and other similar non-value add tasks.

3300 lbs max payload

A real cruiser

2.8 mph top speed

A tight fit

6′ aisles

Covers the right ground

< 200 meter distances

Plug ‘n play

2.5 hrs quick-change battery

FEATURES AND FUNCTIONALITY

Maximize Your Workforce

Agility in tight spaces

Navigate and stage pallets with less than 6 feet of wiggle room

Autonomy over short distances

Delivers value for loads that move less than 200m

Improves lower throughput work

Alleviates labor challenges by automating low-volume operations and non-value add microworkflows

Flexible configurations

Designed to move a variety of pallets, carts, racks, bins, and other payloads up to 3,300 lbs. / 1,500 kg

Manual assignment / autonomous execution

Switches between autonomous operations and manual control via on-board tablet

Quick-Change Battery

Equipment-free, manual battery swap every 2.5 hrs for 24/7 availability

ANSI/ITSDF B56.5 and RIA 15.08 compliant

Keeps your employees, equipment and goods safe

24/7/365 Support

99.9% uptime via our Pivotal™ Command Center

CaseFlow™

Ready to Double Your Case Picking Productivity?

Discover how CaseFlow, powered by the Vecna CPJ, can transform your warehouse operations with smarter automation and seamless human-robot collaboration.

Optimize your warehouse workflows

By implementing CaseFlowTM, we were able to increase picking efficiency by over 100% while improving worker retention and overall safety.

ANDY JOHNSTON Senior Director of Innovation, GEODIS

Let’s go

Optimize your critical workflows right now

Have questions about what Vecna can do for you? Tell us about yourself, and an automation expert will be in touch shortly.

Thank you for getting in touch

We aim to respond to all messages within 1-2 business days.

In the meantime you might be interested in some of these resources.