Power up with Pivotal™

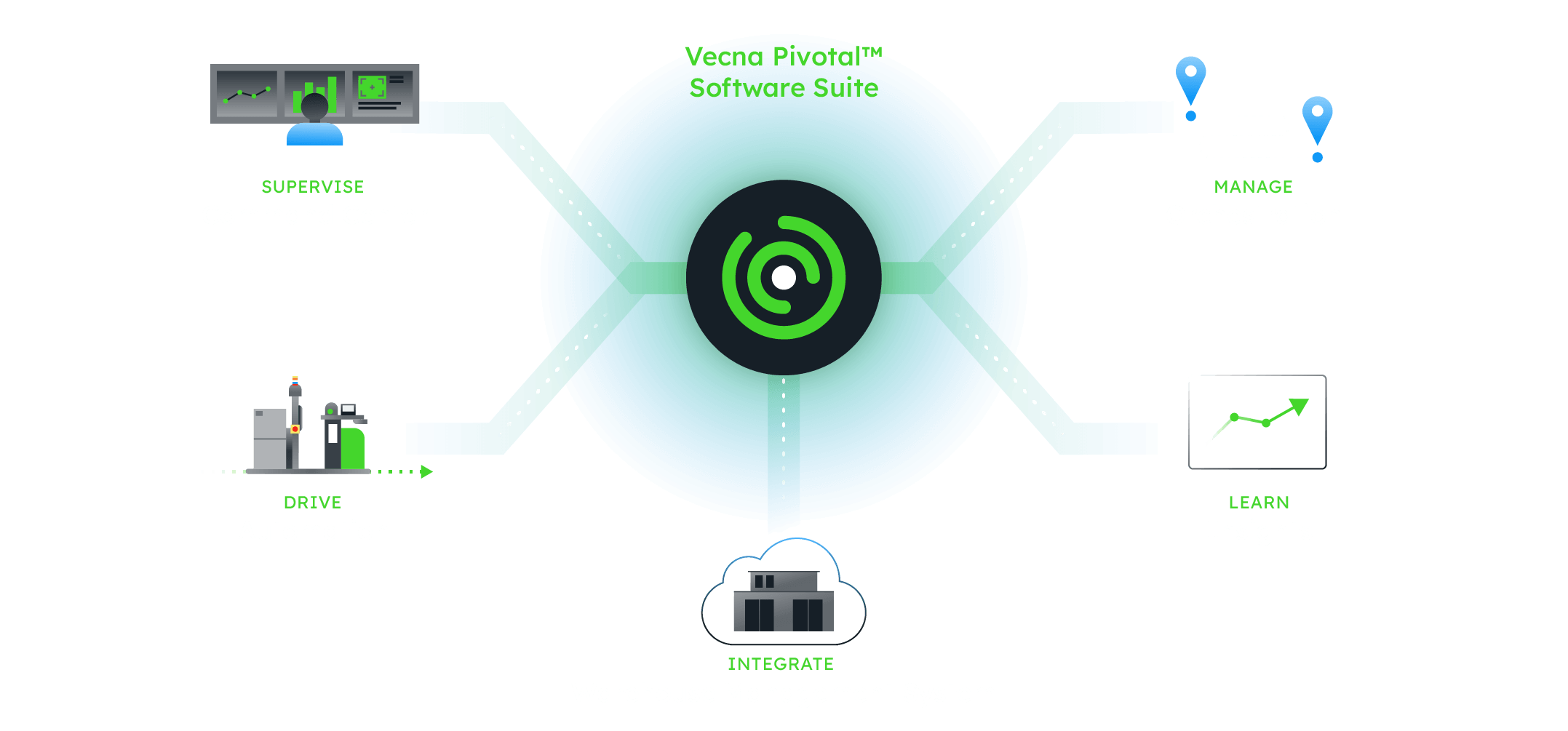

Meet Pivotal™, the world’s first end-to-end orchestration software suite exclusively for material handling automation.

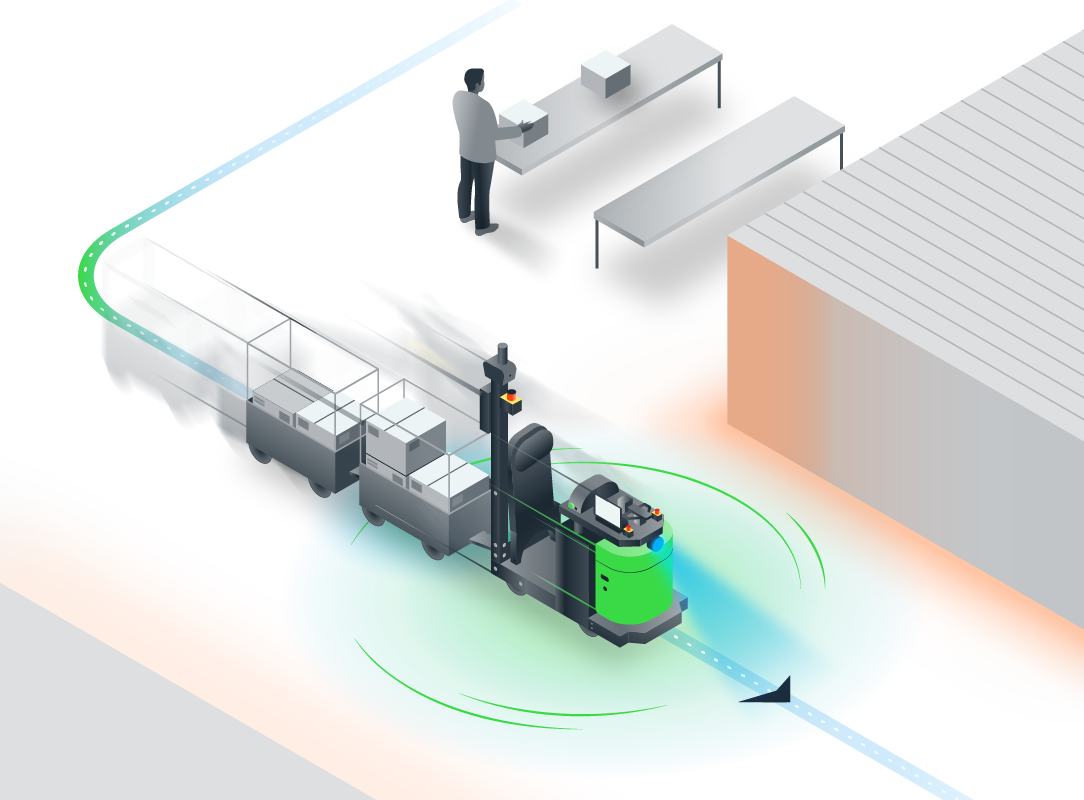

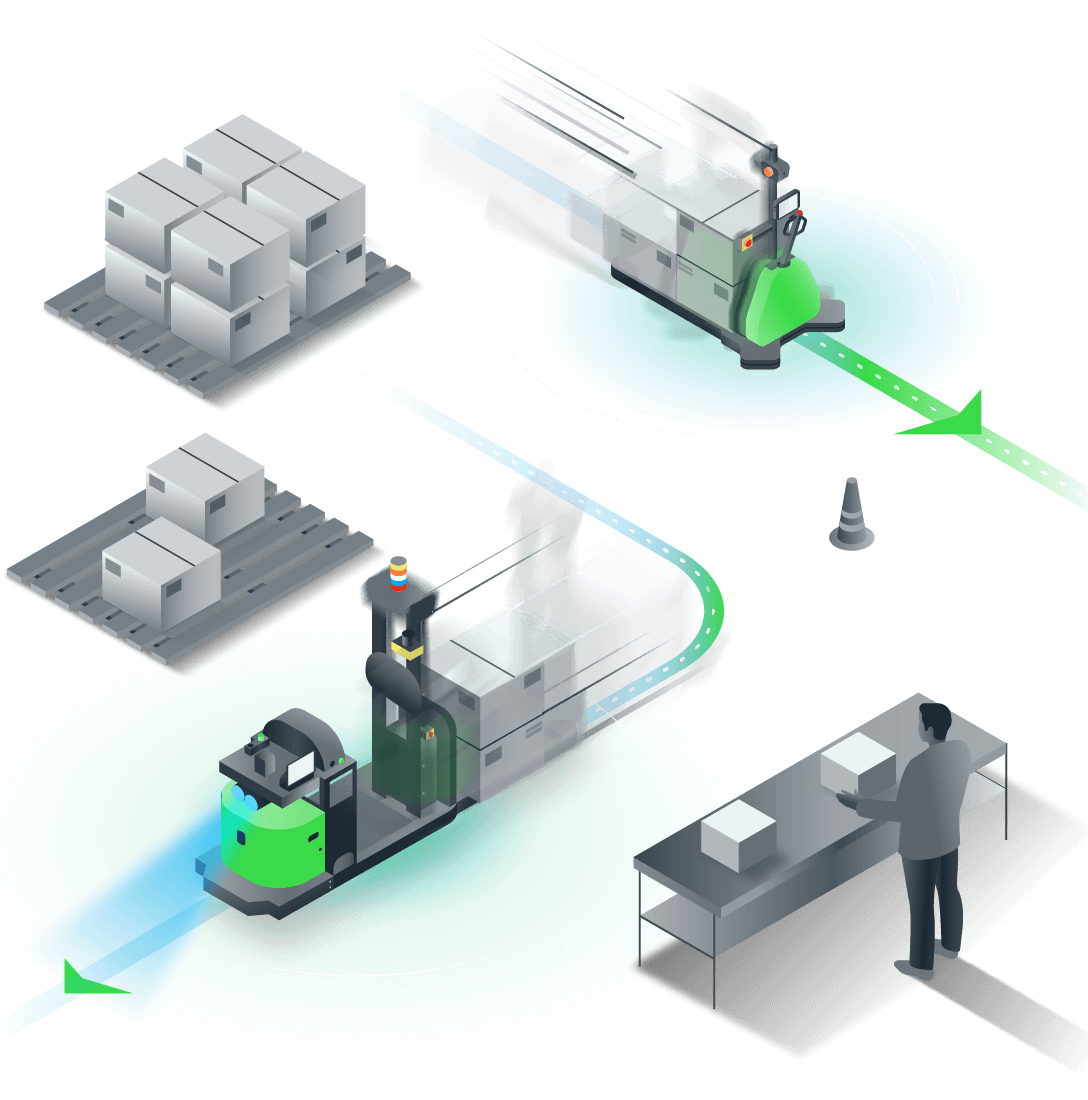

Human-in-the-loop-automation

Maximize uptime

Stay up and running in situations where traditional AGVs grind to a halt. Our 24/7/365 command center combines human intelligence with powerful technology to bring you greater flexibility and performance in complex circumstances.

99.9%

uptime

< 1%

local assist rate

Monitor your fleet

Stay in the know, keep on the go. We help to maximize your system’s performance with real-time monitoring. Day-to-day visibility into your fleet helps us solve immediate problems quickly keeping your goods moving.

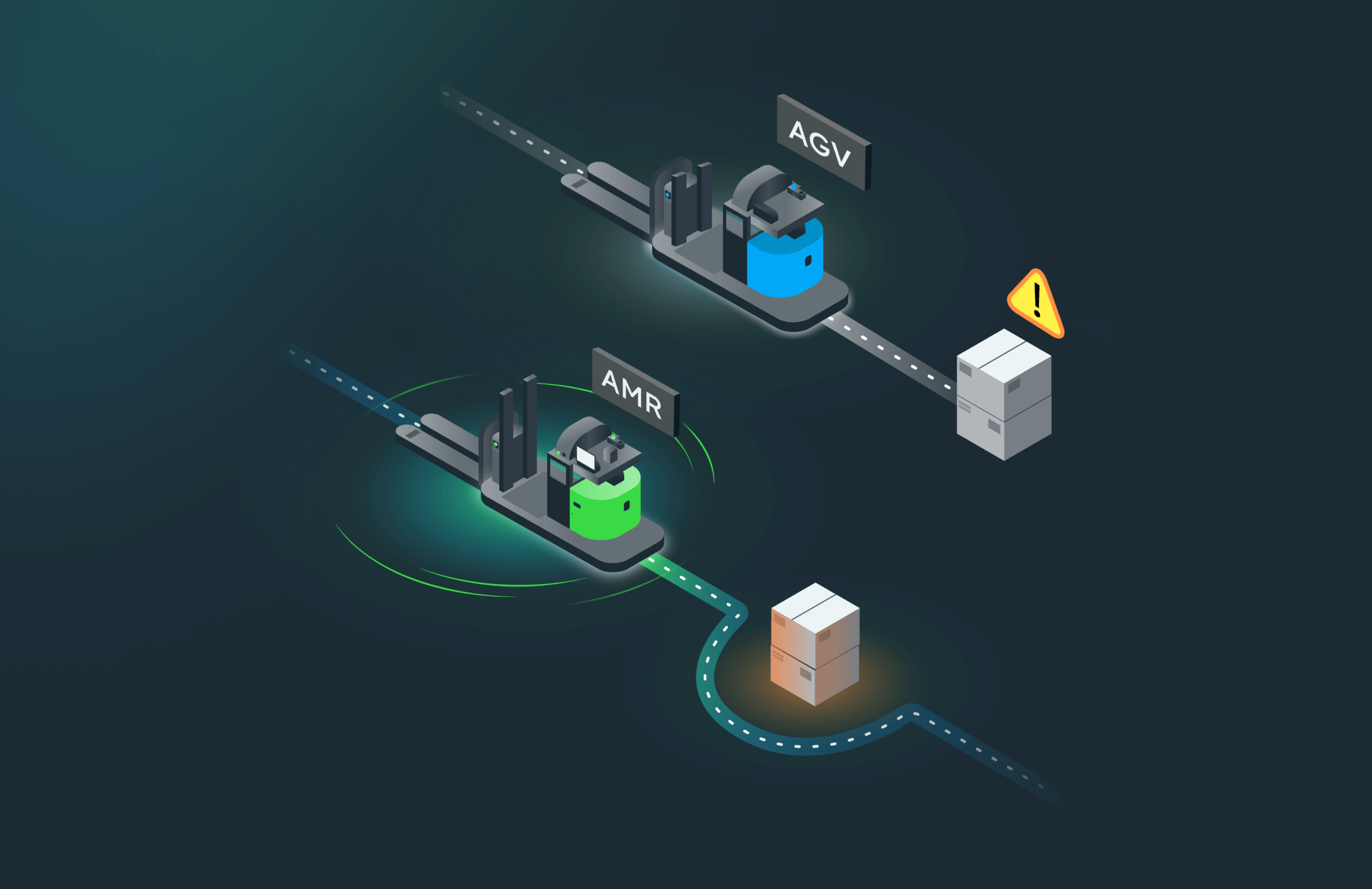

Resolve in real-time

We solve common problems, like false sensor readings, and lost localization, before they affect productivity. Our remote resolution allows us to fix issues without deploying an operator on the floor.

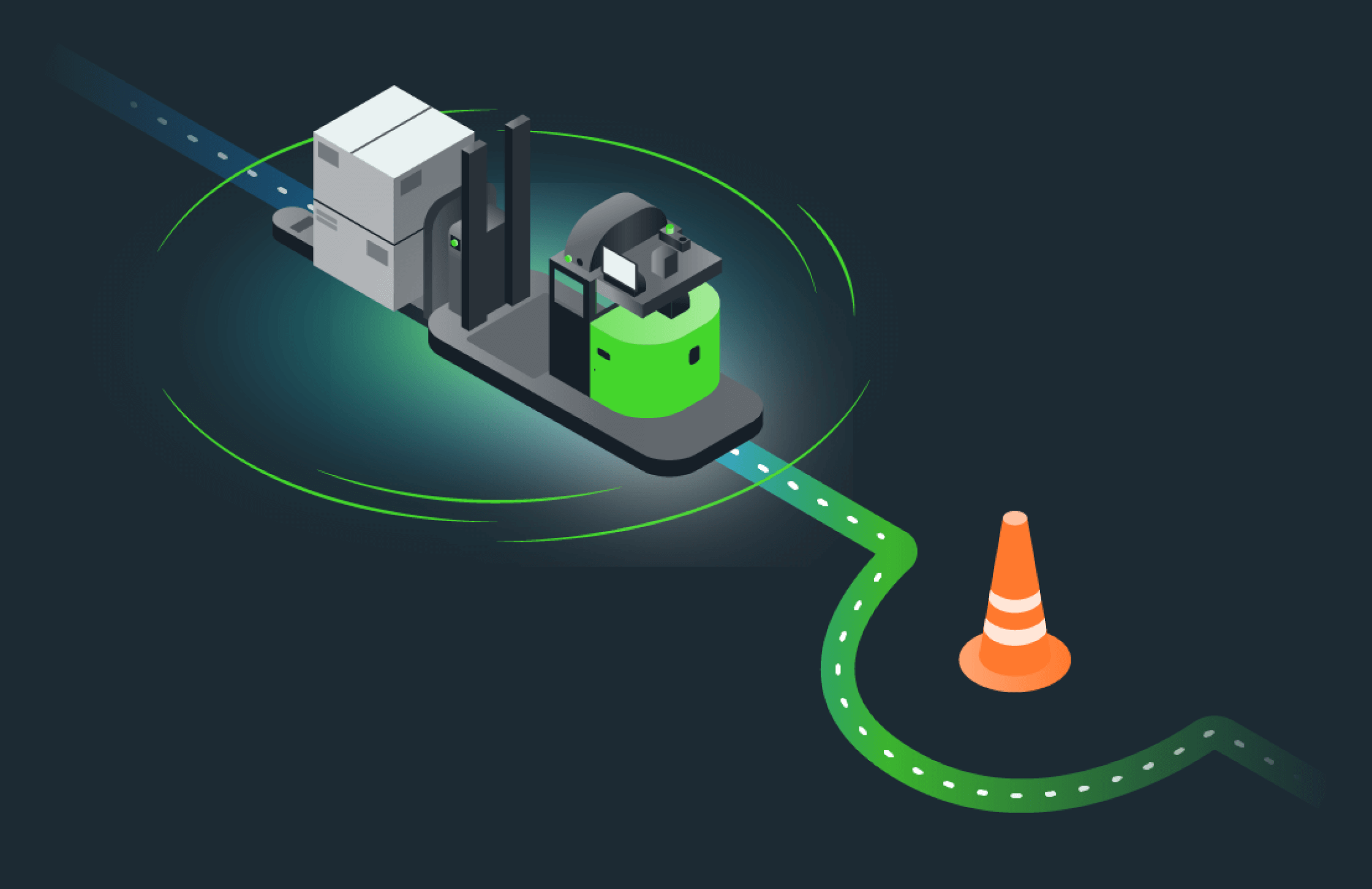

Teleoperate edge cases

Keep rolling even when encountering edge cases, such as obstacles preventing automatic recoveries or pallets staged outside of spec. Our always-on teleoperators help you perform where machines fail.

Fix it faster

Limitless support yields limitless productivity. The Pivotal™ Command Center ensures you get the help you need without a wait time, with a local assist rate of < 1% of operating time.

Orchestration

Tune your operations like a conductor

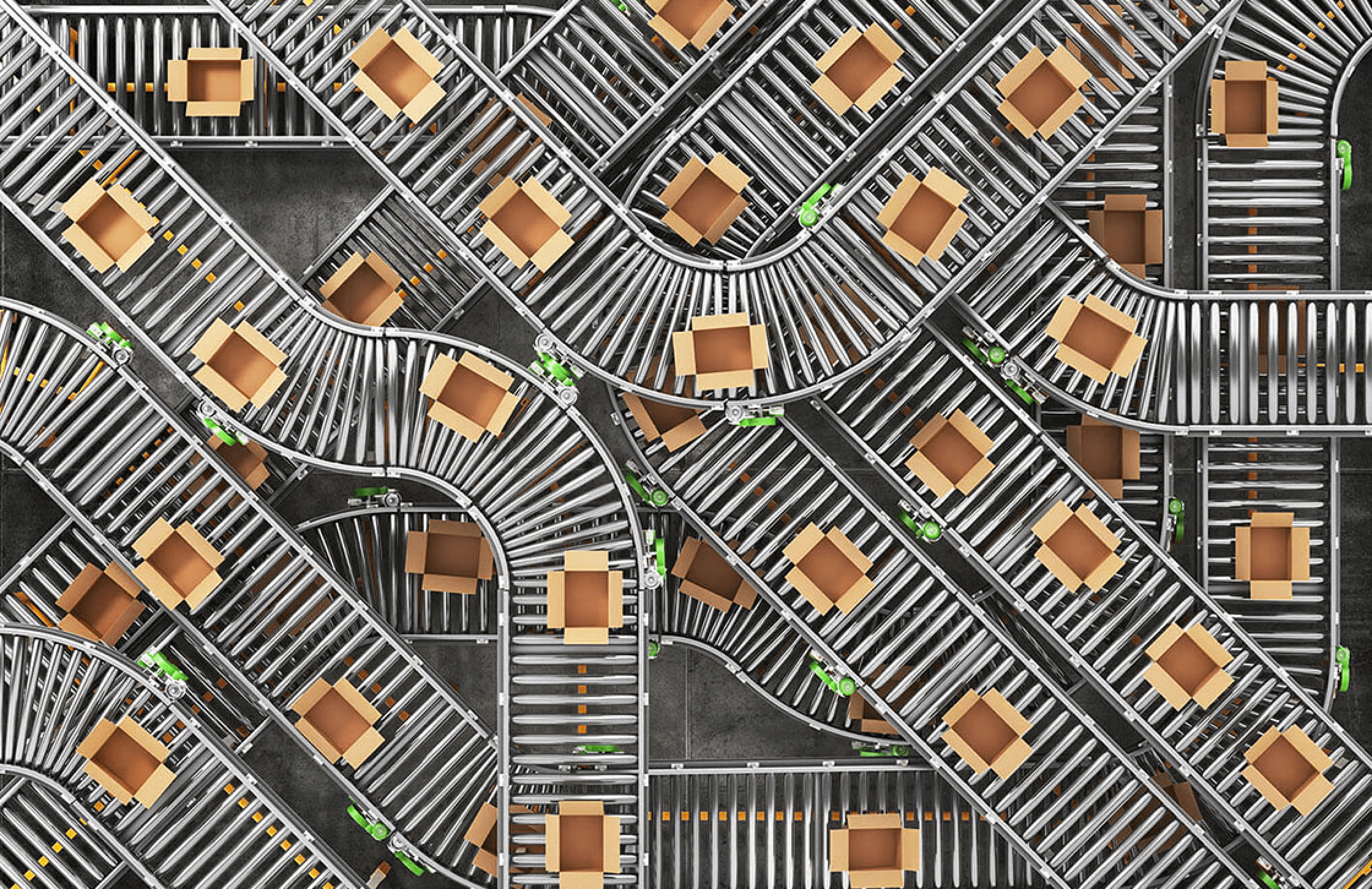

Get the right resource to the right task, on the right route, at the right time. Pivotal™ orchestration aggregates data across resources to optimize how your materials flow in real-time.

Get eye-in-the-sky control

More data, more moving. Pivotal™ aggregates demand from multiple sources across your operation – including directly with WMS / ERP, tablet UIs, call buttons and PLCs – insuring routing and resource allocation is informed by a complete and real-time picture of your entire operation.

Optimize work execution

Run at peak efficiency no matter what changes on the floor. Pivotal™ dynamic task allocation uses data based on location, status, availability and KPIs to update and adjust the plan in real-time.

Balance demand congestion

Goodbye gridlock. Pivotal™ keeps your materials moving even in high traffic areas – balancing demand with congestion, charging and fleet management to maximize your overall throughput.

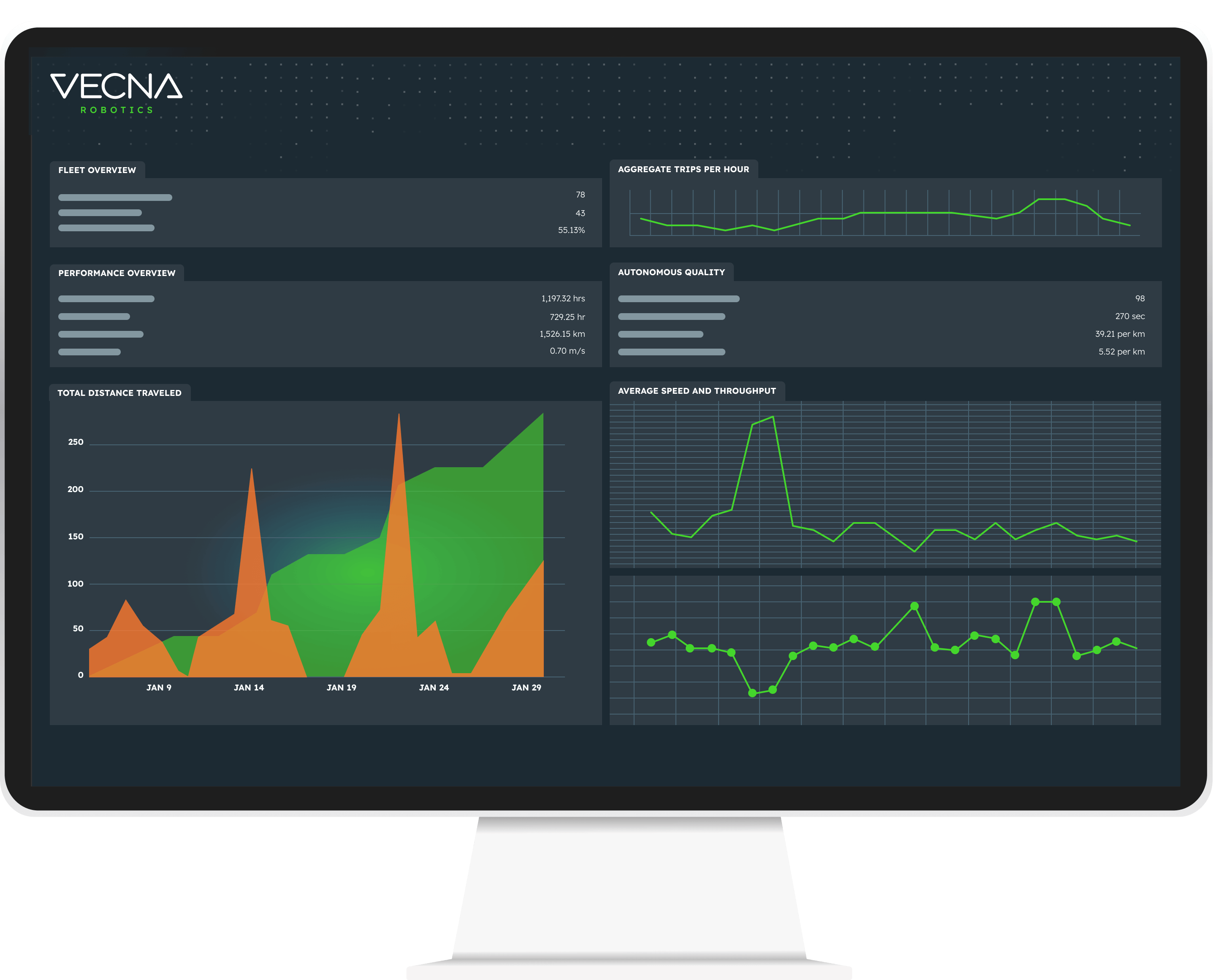

Insights

Knowledge is throughput

Pivotal™ data streaming, analytics and user-friendly dashboards help you transform your data into actionable insights that drive your business forward. Tap into performance trends, heatmaps and industry-unique analytics to improve your operational performance over time.

Measure your workflow performance

Stay on a winning track. Pivotal™ analytics help you track your KPIs over time as well as identifying areas for expansion and improvement.

Drive for continuous improvement

Get full visibility. Pivotal™ monitors system performance, adoption and ROI as automation grows throughout your network, providing you with the data you need to drive continuous improvement.

Join our “performance network”

Leave behind fixed output and leverage the full power of the internet of things. Pivotal™ uses performance data collected from every robot in Vecna’s entire fleet to the improve the system via a data-driven feedback loop.

Integrations

Seamless operations from the inside out

Our platform integrates with your facility’s processes, people and systems to deliver a seamless automation experience with your existing infrastructure.