What are finished goods?

Finished goods refer to products that have completed the manufacturing process and are ready for sale or distribution to customers. These goods are typically manufactured in batches and are stored in warehouses or distribution centers until they are sold. The process of producing finished goods typically involves several stages, including raw material sourcing, production, quality control, and packaging.

Advantages of finished goods

One of the main advantages of producing finished goods is that it allows companies to respond quickly to changes in consumer demand. For example, if a company produces finished goods, they can quickly adjust production levels to meet increased demand for a particular product. This is in contrast to companies that produce goods to order, which may take longer to respond to changes in demand.

Another advantage of producing finished goods is that it allows companies to take advantage of economies of scale. By producing goods in large quantities, companies can reduce the cost per unit of production. This can help to increase profitability and make the company more competitive in the marketplace.

Requirements for finished goods

The production of finished goods also requires careful planning and coordination. Companies must ensure that they have the necessary raw materials, equipment, and labor to meet production deadlines. They must also ensure that their finished goods are packaged and stored correctly to prevent damage or spoilage.

In order to manage inventory effectively, it is important for companies to track their finished goods inventory levels. This can be done manually, or by using inventory management software. This software can help companies to identify which products are in high demand, and which are not selling as well. This information can then be used to adjust production levels and optimize inventory.

Finally, companies must also ensure that their finished goods meet the required quality standards. This can be done through quality control checks at various stages of the production process. It’s important to ensure that the products meet the specifications, and also to ensure that they are safe for use.

The role of automation with finished goods

Automation plays a crucial role in the production of finished goods. By automating various stages of the manufacturing process, companies can increase efficiency, reduce costs, and improve product quality. Automation can also help to reduce human error and increase consistency in the production process.

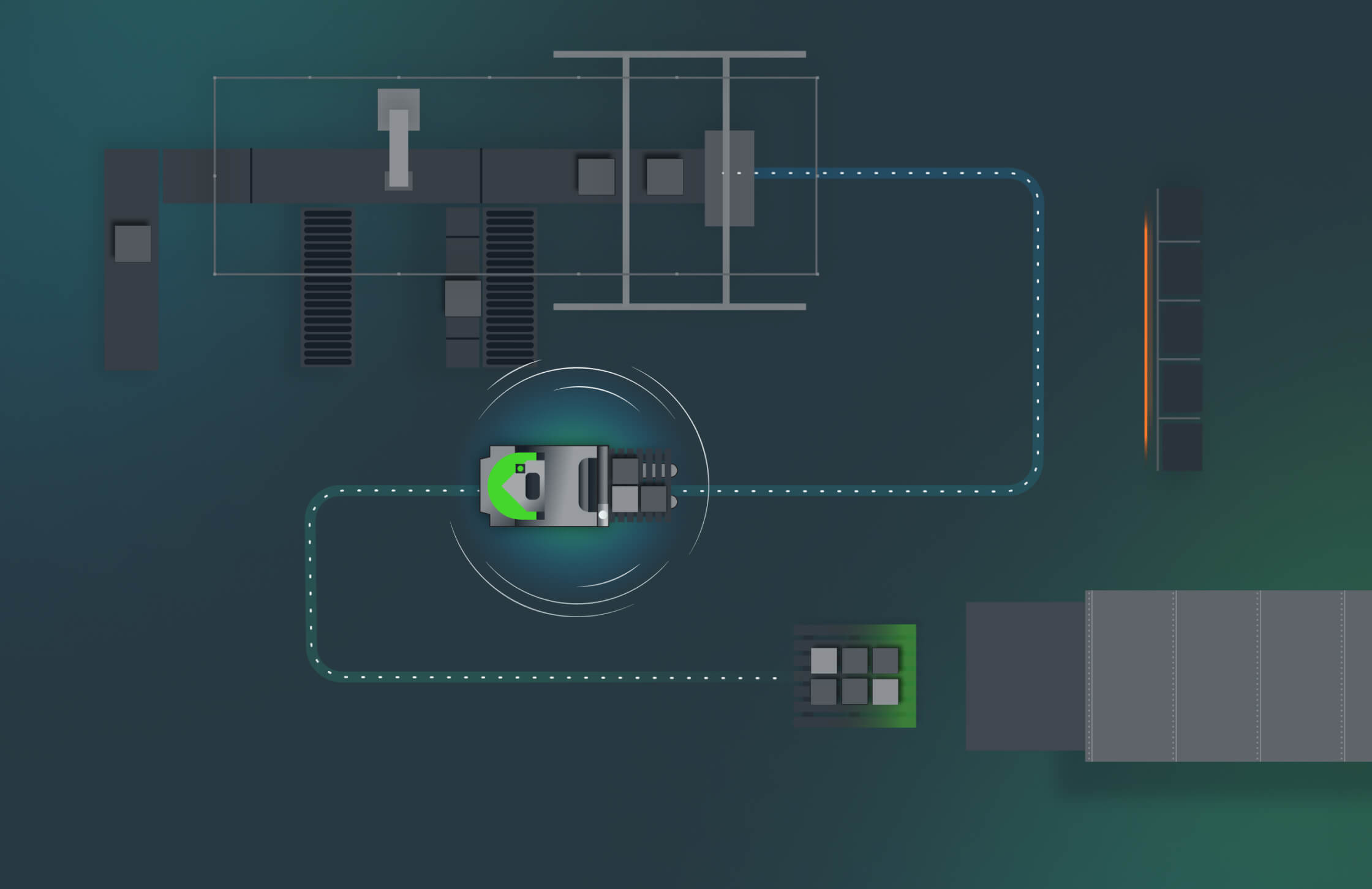

One of the most common forms of automation used in manufacturing is the use of robots that can be programmed to perform a wide range of tasks, such as welding, painting, and assembly. Robots like AMRs, for example, can also be used to move materials around the factory, reducing the need for human labor. Additionally, robots can be used to monitor and control the production process, ensuring that all stages are running smoothly.

Another form of automation used in manufacturing is the use of computer-aided design (CAD) and computer-aided manufacturing (CAM) software. These programs allow manufacturers to design and plan the production process, and then use the information to control and monitor the machines used in production. This can help to improve the efficiency of the manufacturing process and reduce the need for human labor.

In addition to increasing efficiency and reducing costs, automation can also help to improve product quality. Automated systems can be programmed to perform quality control checks at various stages of the production process, ensuring that all products meet the required standards. Furthermore, automation can help to reduce human error, which can be a major source of product defects.

Finished goods refer to the products that are ready for sale or distribution. Automation plays a crucial role in the production of finished goods by increasing efficiency, reducing costs and improving product quality. Automation can be achieved by using robots, computer-aided design and computer-aided manufacturing software. Automation in finished goods also allows for better monitoring, control and quality checks, reducing human error.

Finished goods automation solutions

Fortunately, Vecna Robotics has a wide range of solutions that are tailor-made for automation finished goods operations. For more information about how you can get started with your finished goods automation journey, go to our From No Bot to Robot page, or can contact us today to schedule a consultation with a factory automation expert.