When Eli Whitney introduced the concept of lean manufacturing, few people could’ve predicted that robotics in manufacturing would unlock a whole new way for manufacturers to cut waste and produce a higher-quality product even faster.

Most modern manufacturers will claim to be proponents of lean manufacturing, a production process based on principles that aim to maximize productivity and minimize waste. However, while some see lean manufacturing only as a way to ruthlessly eliminate excess in their facilities, the real goal is not just about cutting tasks, processes, and resources but rather about delivering increased, sustainable value to the customer.

Lean manufacturing reduces production time and costs by focusing solely on processes, activities, and services that add value to the customer. Pioneered by scientists, engineers, and innovators, the history of lean manufacturing dates back hundreds of years and provides valuable strategies to improve the bottom line and speed up production. From its earliest beginnings in mass manufacturing to its current use of robotic automation, lean has a rich history worth exploring for those seeking to understand the business impacts of robotic automation solutions and their role in lean manufacturing. Let’s dive in.

The origins of lean manufacturing

In 1779, Eli Whitney agreed to deliver 10,000 muskets to the U.S. Army within a year – an unheard-of feat at the time. Whitney did not meet his deadline, but he did produce the rifles in record time by making the muskets out of compatible parts that could be easily mass-produced and replaced. Interchangeable parts standardized the manufacturing industry’s processes and eliminated extraneous steps, enabling unskilled workers to make and repair weapons quickly at a fraction of the price.

By the late 1800s, the majority of the industrial world adopted the concept of interchangeable parts, including a mechanical engineer named Frederick W. Taylor. Taylor believed he could further improve worker efficiency by continuously monitoring a task and recording how long it took to complete, ultimately discovering the optimal performance rate.

Taylor’s work was expanded by Frank and Lillian Gilbreth, who monitored workers’ behavioral and psychological aspects as they completed each task. These findings, along with Taylor’s, became known as the Motion-Time Study. The two studies broke down individual tasks into simple steps, allowing one to identify and eliminate any non-value-added work. The findings fueled the Industrial Revolution.

Henry Ford is synonymous with the Industrial Revolution. But it was a pattern maker within his Detroit automobile plant, Charles E. Sorensen, who examined the relationship between people, machines, tooling, and products and organized them to achieve a continuous flow production flowenson’s invention became known as the assembly line.

At its core, the assembly line standardizes a process and eliminates waste to achieve cheaper and faster results without sacrificing quality. The universal notion of lean manufacturing was still unknown and unlabeled, but the massive savings produced by the assembly line were undeniable.

By 1948, Toyota Motor Company engineers, Taichii Ohno and Sakichi Toyoda, were utilizing the assembly line but were eager to find and eliminate more waste.

They realized inventory accounted for a lot of waste, and there was no system in place to manage it. This observation led Ohno and Toyoda to design the Toyota Production System (TPS) or Just-in-Time production, eliminating waste by making only what is needed, when it is needed, and in the needed amount.

Toyoda and Ohno highlighted eight key areas of waste: defects, overproduction, waiting, non-utilization of talent, transport waste, inventory, motion, and excess processing. By reducing these eight factors, an organization conserves resources to provide the best quality, lowest cost, and shortest lead time.

Toyota used TPS as a method of manufacturing cars, but the concept applied to the rest of the industrial world. It became known as lean manufacturing after a quality engineer from Toyota wrote his master’s thesis on TPS and entitled it “The Triumph of Lean Manufacturing.”

While the execution of lean manufacturing is highly specific to an organization, the eight types of waste identified are constant. Failure to consider these variables slows down production lines and decreases quality, ultimately resulting in unhappy customers and financial loss.

The future of lean manufacturing and robotic automation

That brings us to the complicated and fast-paced economy of 2023. As e-commerce and direct-to-consumer demands race forward, companies are discovering that the processes and tools that have helped them execute lean principles in the past can’t keep up with the current pace of demand in a safe, reliable, and profitable manner.

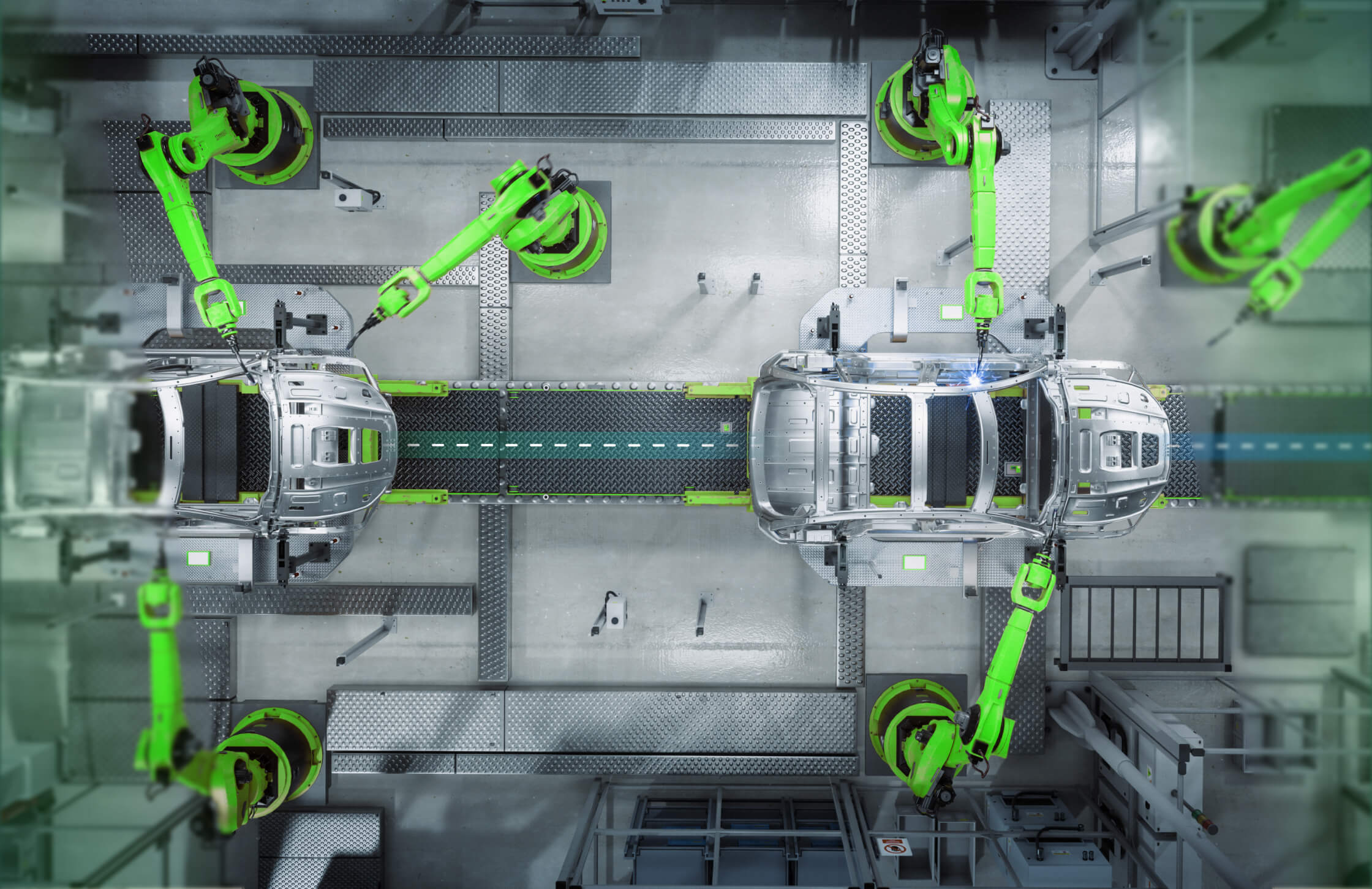

To match growing customer expectations and remain competitive, manufacturers and warehouses must find new ways to cut waste and produce a higher quality product quicker. Enter Robotic automation.

Whereas past industrial robots may have only been considered a replacement for standardizing repetitive tasks on an unchanging assembly line, modern automated robots are much more than static helpers. Automated mobile robots (AMRs) such as Vecna’s have evolved to match the flexible, dynamic, and ever-changing needs of warehouses and manufacturers. These AMRs address many of the eight key areas of waste, as listed by Ohno and Toyoda. Robots:

- Remove defects from the logistics process

- Function as just-in-time solutions to meet current production levels

- Can be deployed for a variety of functions, eliminating waiting and wasted time

- Properly utilize the functions of all warehouse assets, including robots and human workers, through sophisticated software

- Streamline transport times and routes by following a directed path and learning from each experience to become even more efficient

- Produce no wasted movement

- Robots have powerful advantages: precision, efficiency, data collection, and repetition. Humans also possess inherent strengths: reasoning, emotional intelligence, and generalization.

The right robotic solutions merge the best of what humans and robots can do by utilizing the high-value strengths of each resource and eliminating non-value adds – the ultimate goal of lean manufacturing. Vecna’s robust fleet of automated mobile robots integrate seamlessly into lean manufacturing processes – providing manufacturers with new, safe, and effective ways to cut waste and increase productivity:

- The Vecna ATG is an autonomous tugger built to handle high-capacity pallets and can move materials that don’t fit in conventional systems, improving throughput by up to 45%.

- The Vecna CPJ is a co-bot pallet jack optimized for tight spaces and quick movements for tasks such as replenishment, waste/dunnage retrieval, empty pallet consolidation, pick-to-pack out and similar non-value adding activities.

- The Vecna AFL is a versatile driverless automated forklift that can move a wide range of payloads and pallet types and workflows – from ground-to-ground to conveyor belts and riser lifts.

If you’re ready to get started with an initial assessment, contact us to set up an appointment with a Vecna Robotics automation expert.