At $10/hr we make manufacturing go

Escape rigid, last-generation automation, sluggish retooling and unsustainable labor costs. Our unique approach to material handling delivers intelligent, flexible automation engineered to get your goods through the line and out the door fast.

Trusted by industry leaders

Respond and adapt with ease

The pressure is on to be nimble and adapt rapidly to e-commerce and mass customization demands. Stay competitive with flexible material handling automation that helps you scale and adapt quickly.

Accelerate your time to value

The market demands speed. Reality demands 3+ years for new plants to come online. Shift your ROI into high gear. Vecna’s infrastructure-free install and Robots as a Service model eliminate the need for capital expenditure and decreases overall cost by 33% vs. manual MHE.

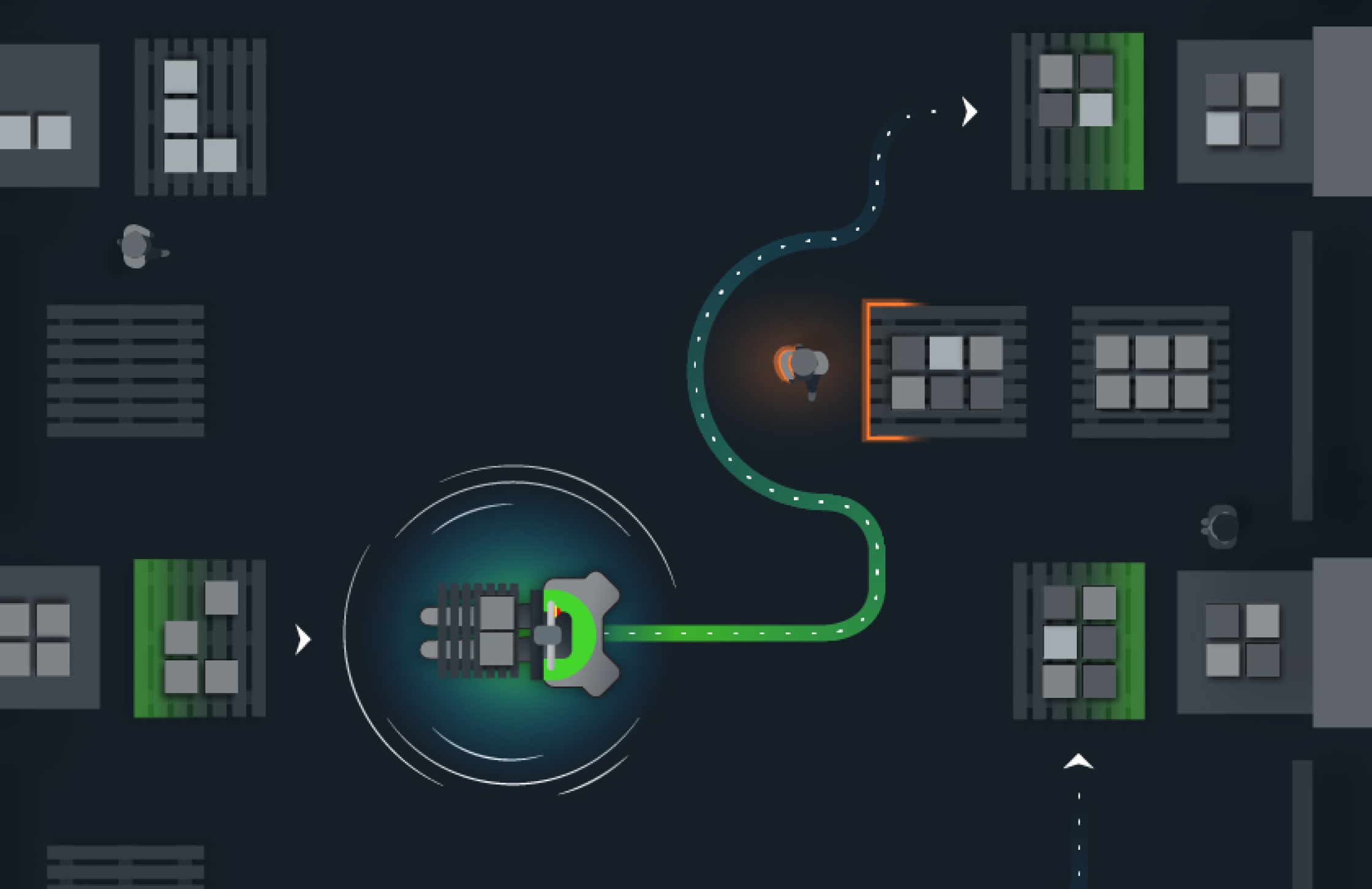

Get flexible, scalable automation

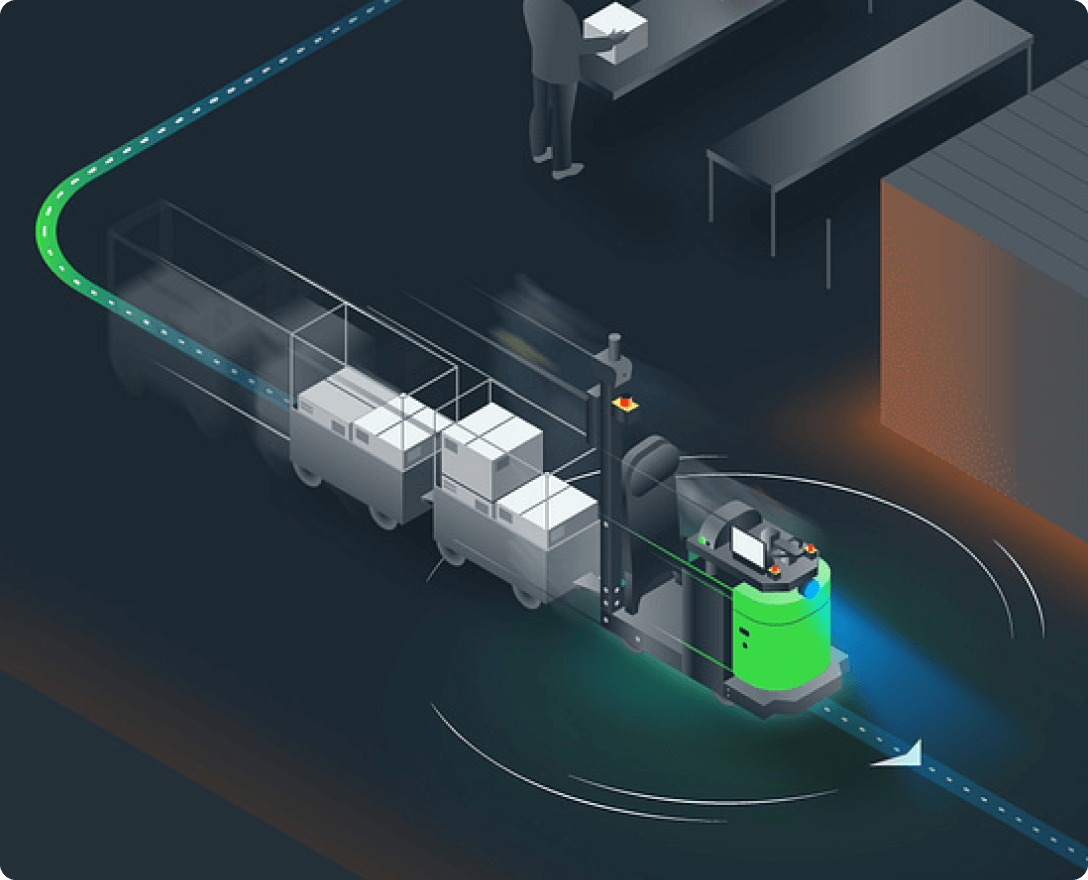

More low-volume/high-mix manufacturing, more retooling. Get it done faster and stay nimble with Vecna. Our autonomous mobile robots (AMRs) – next-generation automated guided vehicles (AGVs) – utilize infrastructure-free navigation and reconfigurable automation that adapts to operational conditions, materials, assemblies and plant layouts.

Drive continuous improvement

Future-proof your productivity with data analytics that provide unprecedented visibility into how your facility operates now and into the future.

Deploy with speed

Accelerate your automation journey from zero to full capacity in weeks, scaling with your business needs.

New facilities require new thinking

Your supply routes are disrupted, but the market requires more speed and responsiveness. Reshoring to North America is now a reality, but don’t be derailed by spiking labor costs and local supply chain chaos. Vecna’s material handling automation system helps your low-volume/high-mix production keep up with demand while optimizing your OEE.

Lower operating costs and increase throughput

The skilled labor pool keeps shrinking. Labor costs continue to rise. Vecna’s dynamic intelligent routing covers the labor gap to deliver more dependable takt times and just-in-time delivery, as well as lower operating costs and higher productivity.

Achieve 99% uptime

Blips happen. Keep moving despite them. Our 24/7/365 remote monitoring uses human-in-the-loop automation to keep robots operating in complex situations. With an on-site manual assist rate less than 1% of operating time, you can stay up and running all the time, every time.

Lean into safety

With a safety rating that outperforms the industry standard, Vecna’s automation can help you achieve your lean initiatives for improved safety and fork-free floors while reducing waste.

Industries Served

The Vecna System

Speedy robots, rapid ROI

Power-up your operation with the automation that delivers value from day one and scalability over the long term.

$10/hr

per robot, or less!

<1

year to positive ROI

24/7

remote monitoring of your robot fleet

100%

guaranteed customer-defined performance

Return on Robotics (ROR) Calculator

What can Vecna do for your plant? Find out how much Vecna can lower your costs and increase your throughput in just a few seconds.

Let’s go

Optimize your critical workflows right now

Have questions about what Vecna can do for you? Tell us about yourself, and an automation expert will be in touch shortly.

Thank you for getting in touch

We aim to respond to all messages within 1-2 business days.

In the meantime you might be interested in some of these resources.