SUPPLY CHAIN DISRUPTIONS

Meet the next shock with resilience

Companies realize that they cannot rely on a small number of offshore partners to maintain a critical supply chain. In order to build more resiliency, companies need to diversify their suppliers as well as augment supply chain operations with flexible automation.

Automation to the rescue

Automate your way to supply chain resilience

Before the next supply chain shock has a ripple effect through your supply chain, it’s time to build more resiliency throughout your operations. Automation can help you to quickly adapt to changing operations and give you the visibility, control and flexibility you need to keep goods flowing with every supply chain challenge that is thrown your way.

Adaptability

Mordern automation can adpat to changing operations

Flexibility and Scalability

Modern automation systems don’t require massive infrastructe change. Plug and play.

Improved Visibility

New automation systems track parts and assemblies down to the individual component and process step level.

Retains Labor

Automation helps keep employees engaged and makes their jobs more valuable.

Improves Quality

Improves efficiency of operations by delivering more conistent task and cycle times.

Hits the Bottom Line

Do more with less by focusing scarce labor on higher-value tasks.

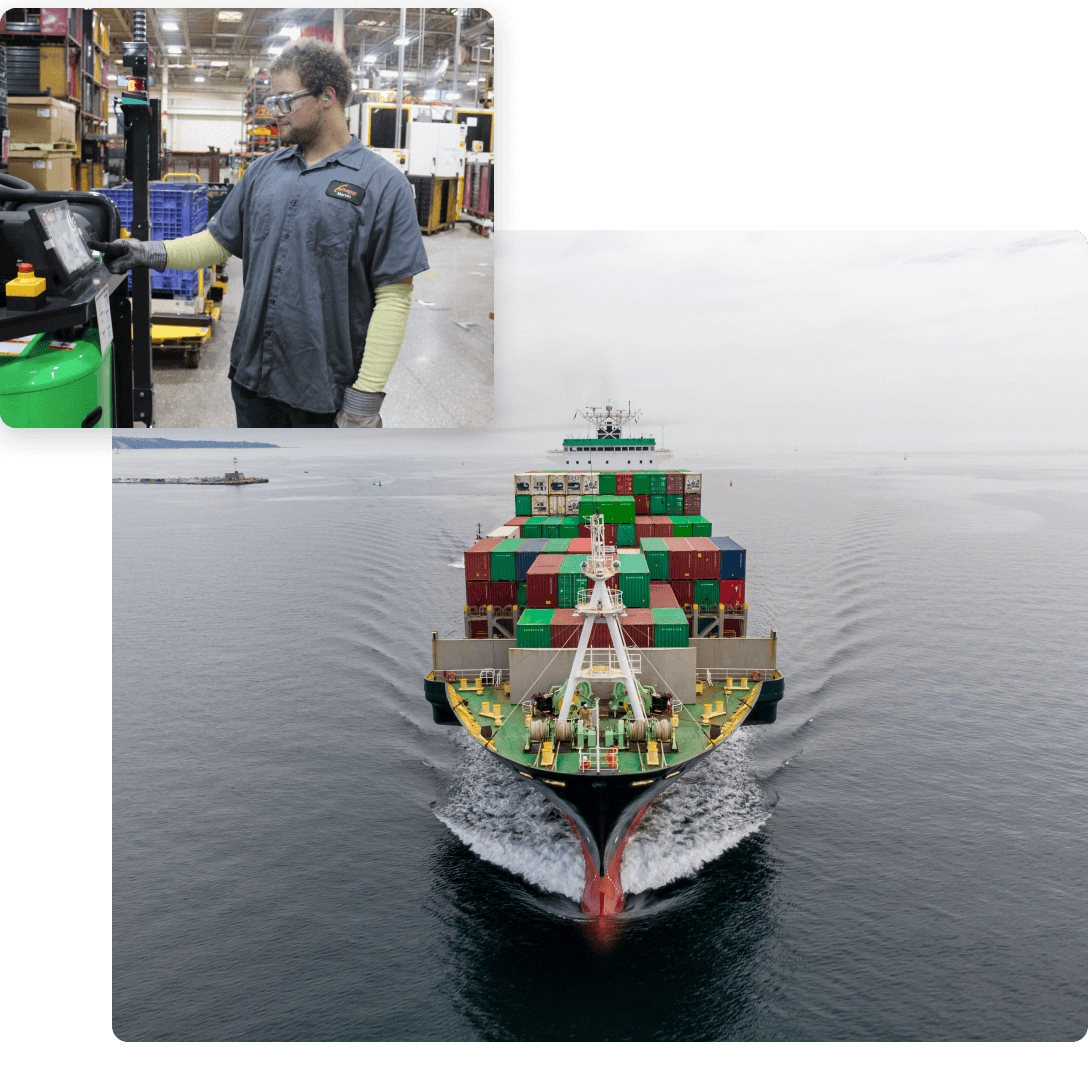

The Problem

Supply chain disruptions are the new normal

From pandemic lockdowns and foreign invasions, to shortages in baby formula and computer chips, major supply chain disruptions are a new reality in modern supply chains.

345%

increase in U.S. container freight rates since 2019

30

year low in U.S. inventory levels

88%

of global shippers plan to diversify their suppliers

SUPPLY CHAIN DISRUPTIONS

Shock and yaw

Supply chain disruptions and shocks are the new normal. Automation can help you to quickly adapt to changing operations and give you the visibility, control, and flexibility you need to keep goods flowing with every supply chain challenge that is thrown your way.