Pivotal™ Autonomous navigation

Feel the need for speed

Pivotal™ Autonomy drives the fastest, smartest, highest performing and most robust autonomous material handling equipment on the market.

Superior Sensor Technology

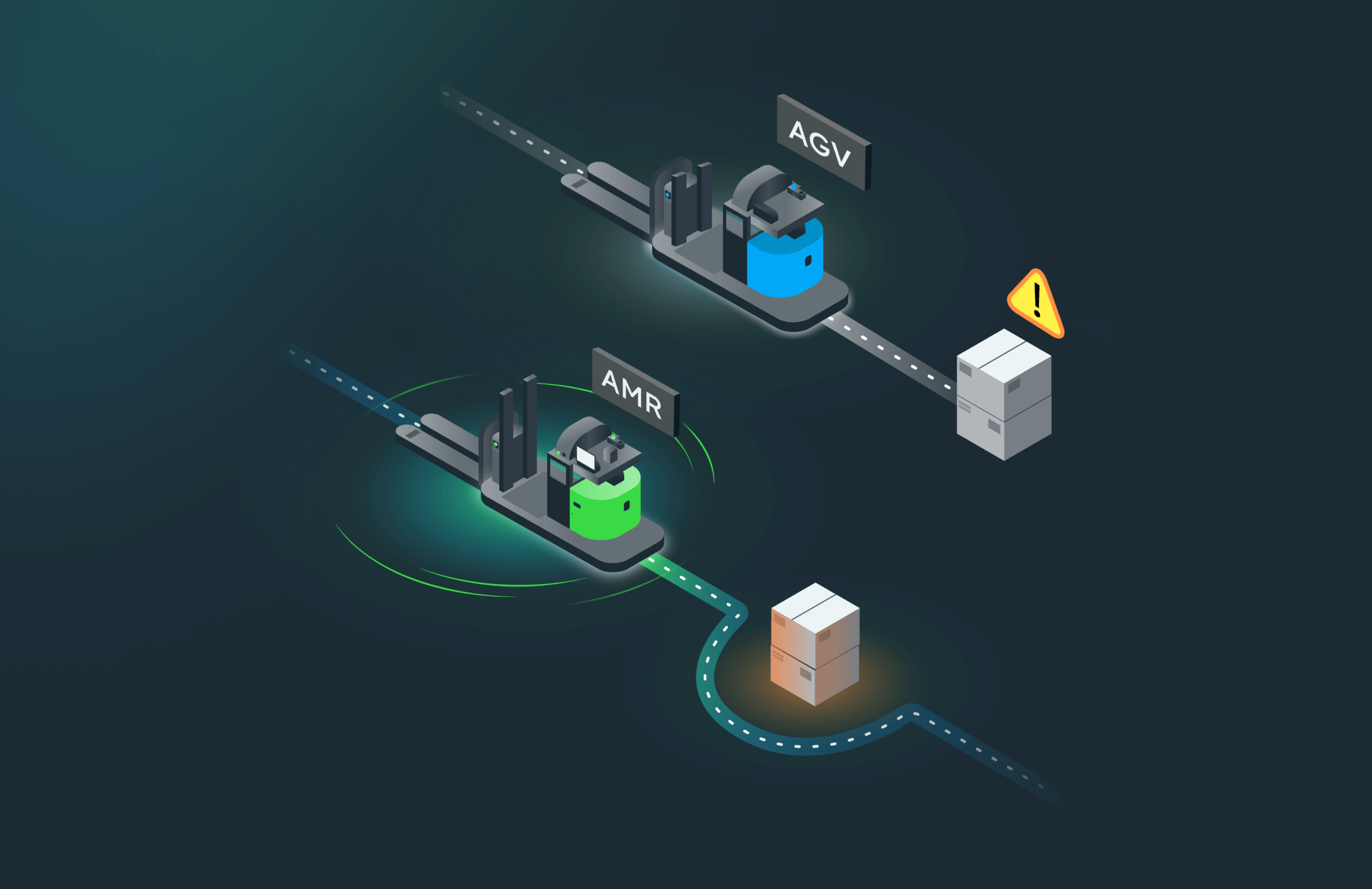

Navigate challenges with AMRs equipped with real vision

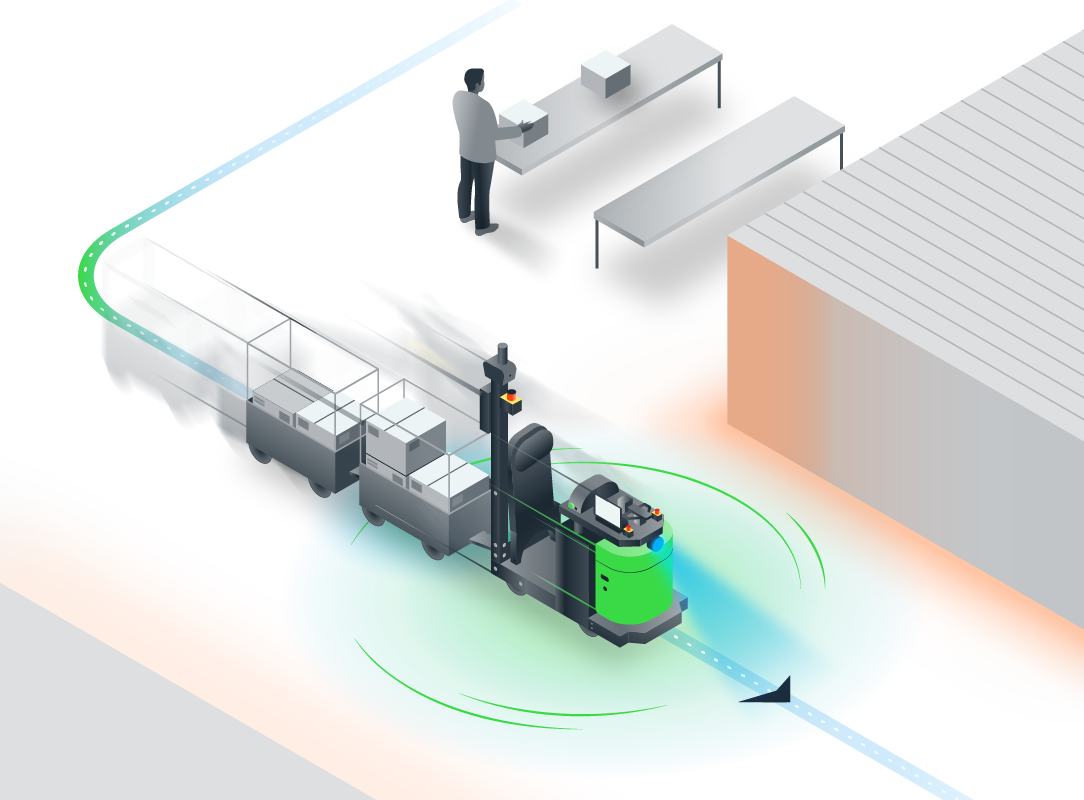

Vecna’s AMRs combine multiple vision and lidar sensors for full 3D sensor fusion perception.. This eye-like perception allows our robots to navigate in high-traffic and unpredictable environments with total confidence.

INDUSTRY LEADING AUTONOMY

Speed, safety and performance

Power-up your operation with the fastest, smartest, highest performing and most robust autonomous material handling solution on the market.

33%

throughput improvement vs. manual operations

1.5x

more pallets moved per $ vs. manual MHE

99.9%

uptime with Pivotal™ autonomy and remote monitoring

0

safety incidents with 3-tier safety architecture

How our navigation works

Move thousands of pallets the easy way

Vecna Robotics’ navigation starts with a virtual map of your entire facility and then the autonomy kicks in.

Step 1: Map

Vecna creates a virtual map of your entire facility’s operating area.

Step 2: Program

Your map is programed with pickup/drop-off locations and rules of the road.

Step 3: Synchronize

Our system connects all routes and synchronizes with all vehicles in your fleet.

Step 4: Route

Each Vecna AMR plots the best available route to complete their missions.

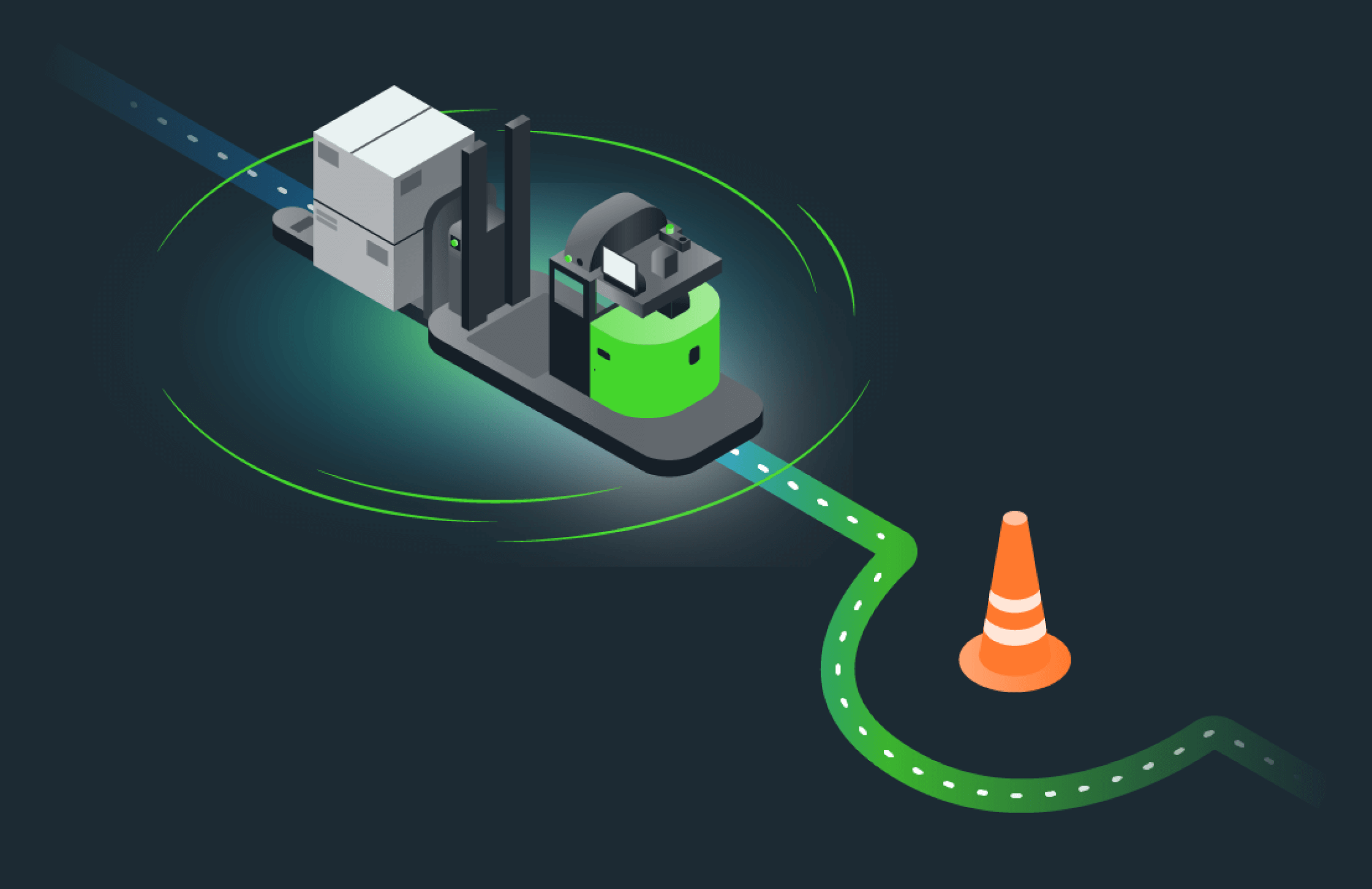

Step 5: Adapt

Vecna’s AMRs safely deviate from prescribed route to avoid obstacles.

Step 6: Go

If congestion is too high on the prescribed route, Vecna’s AMRs will pursue alternative available paths to keep moving.

Your Robot Journey

From no bot to robot at the speed of your business

Your system can be deployed in as little as a few weeks and get to scale as your needs expand.

1 Discover

Identify and prioritize your pain points, choose workflows to focus on, get initial quote.

2 Design

Design solution, approve requirements, obtain sign-offs, and establish start date.

3 Deploy

Rapidly install, run a limited-scale demo that meets KPIs and familiarizes users, on-site training.

4 Learn

Ramp up to full production, 24/7 monitoring by our Command Center, customer success provides bi-weekly analytics and training.

5 Scale

Expand automation to new workflows at the existing site and identify new sites for program growth.

Trusted by industry leaders

and those in the know

Let’s go

Optimize your critical workflows right now

Have questions about what Vecna can do for you? Tell us about yourself and an automation expert will be in touch shortly.

Thank you for getting in touch

We aim to respond to all messages within 1-2 business days.

In the meantime you might be interested in some of these resources.