Workflow Solutions

Case Picking

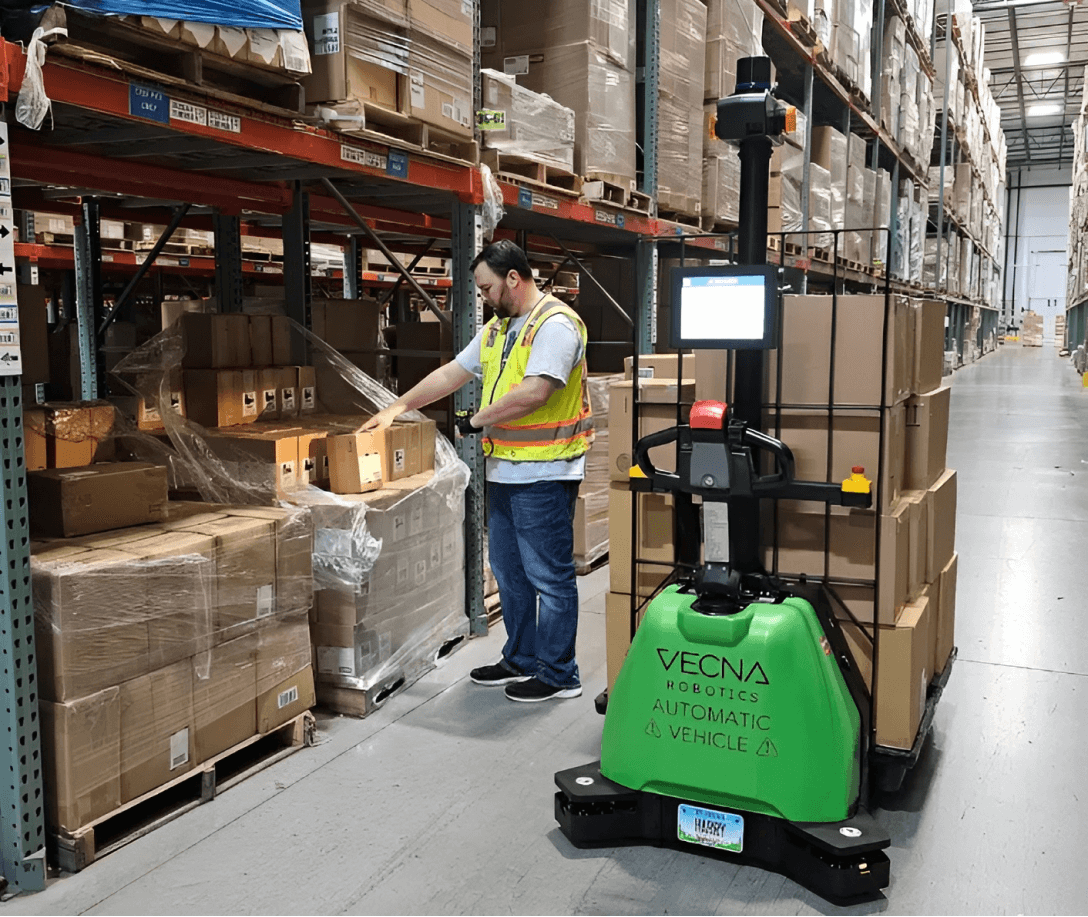

Manual case picking is one of the most labor-intensive and error-prone workflows in the warehouse. Vecna Robotics eliminates wasted travel and maximizes productivity with CaseFlow™ — a high-throughput AMR solution purpose-built for case picking.

The Challenge

Where Labor Goes to Waste

Case picking remains one of the most critical — and inefficient — processes in fulfillment. Traditional workflows rely heavily on manual labor, where workers spend more time walking than actually picking, driving up costs and turnover in high-volume operations.

Common challenges include:

High Labor Dependency

Warehouses often assign dozens of workers to picking tasks, creating staffing challenges and high turnover.

Wasted Travel Time

Studies show up to 50% of a case picker’s shift is spent walking aisles, not picking — leading to lost productivity and fatigue.

Aisle Congestion & Safety Risks

Manual pickers, forklifts, and carts compete for space in narrow aisles, increasing the chance of delays and injuries.

Inconsistent Throughput

Even experienced pickers struggle to maintain speed and accuracy during peak demand or shift changes.

The Solution

Introducing CaseFlow

CaseFlow™ is Vecna Robotics’ end-to-end case picking solution that orchestrates pallet-handling AMRs and human workers in perfect sync. Designed for speed, safety, and scalability, CaseFlow supercharges your fulfillment ops with minimal implementation time and maximum ROI.

CaseFlow

Optimize your case picking operations

-

Automate pallet travel

-

Improve throughput, worker safety and operational continuity

-

Increase UPH by 2x or more

-

Positive ROI in less than 12 months

See how it works

-

Vecna Orchestration Engine receives picklists from your WMS and intelligently optimizes order release.

-

CPJs begin their route at the induction area where they are loaded with a pallet.

-

CPJs visit all pick stops on the pick list, following an optimized route that minimizes travel time and avoids congestion.

-

Wearable UIs tell associates exactly where to go to meet the next CPJ, which cases to load, and what to scan.

-

CPJs meet the associate at the appropriate pick location to complete the pick, then navigates autonomously to its next stop.

-

Completed pallets are dropped off at the designated drop location.

Orchestrate case picking from end-to-end

Why top organizations choose Vecna Robotics

No more robot wranglers

99% uptime with 24/7 remote monitoring

Leading Automation Software

Managing the full flow of work between people, robots, and systems.

#1 in safety

Multi-layered safety systems that exceed industry standards.

Trusted by industry leaders

Earned confidence through years of delivering real-world results.

Stuck in the Case Picking Status Quo?

If your team is still walking miles to move boxes, it’s time for a better way. Learn how warehouse leaders are using orchestration to eliminate wasted travel, boost productivity, and empower workers.

Let’s go

Optimize your critical workflows right now

Have questions about what Vecna can do for you? Tell us about yourself, and an automation expert will be in touch shortly.

Thank you for getting in touch

We aim to respond to all messages within 1-2 business days.

In the meantime you might be interested in some of these resources.