Mobile robot fleet management refers to the coordination and control of a group of mobile robots within a warehouse or distribution center. These robots, also known as autonomous mobile robots (AMRs), are designed to move around a warehouse or distribution center and perform tasks such as transporting goods, picking and packing orders, and conducting inventory management. Mobile robot fleet management is a critical aspect of warehouse automation, as it helps to ensure that the robots are working efficiently and effectively to improve warehouse operations.

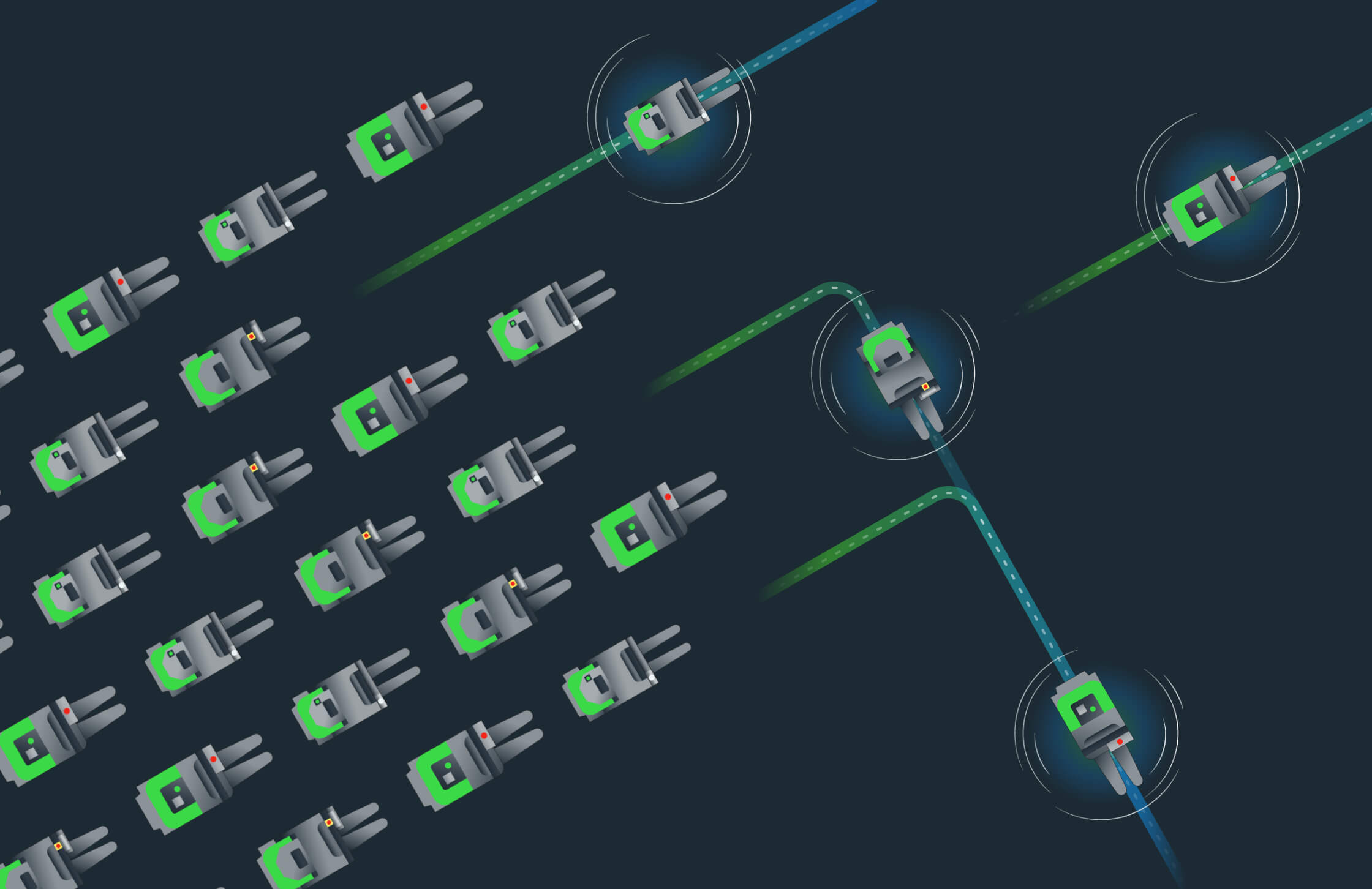

One of the key elements of mobile robot fleet management is the coordination of the robots’ movements and tasks. This includes ensuring that the robots are moving in the most efficient way possible, avoiding collisions and other disruptions, and making sure that the robots are working on the most important tasks at any given time. This coordination is typically managed through a central control system, which can be programmed to prioritize certain tasks, adjust the robots’ routes, and monitor their progress.

Another important aspect of mobile fleet management technology is monitoring and analyzing the performance of the robots. This includes tracking the robots’ locations, identifying any issues or errors that may be occurring, and identifying areas for improvement to achieve maximum efficiency. This data can be used to optimize the robots’ performance, such as adjusting their routes or increasing their speed, to improve overall warehouse efficiency.

Mobile robot fleet management also involves the maintenance and repair of the robots. This can include tasks such as performing routine maintenance, replacing worn parts, and troubleshooting any issues that may arise. It is also important to ensure that the robots are always in good working condition, as a malfunctioning robot can disrupt the entire warehouse operation.

In addition to these technical aspects, mobile robot fleet management also involves managing the human-robot interaction. It is important to ensure that the robots are working in a safe and efficient manner, without interfering with the work of human employees. This can include training human employees to safely interact with the robots, developing clear protocols for robot-human interaction, and ensuring that the robots are easily distinguishable from humans.

Overall, mobile robot fleet management plays a crucial role in warehouse automation. It helps to ensure that the robots are working effectively and efficiently to improve warehouse operations and that the robots are properly maintained and repaired to minimize disruptions. Through proper mobile robot fleet management, warehouses can increase efficiency, reduce costs, and improve customer satisfaction.

Mobile robot fleet management is the coordination, control and monitoring of a group of mobile robots in a warehouse or distribution center. This includes coordination of robots’ movements and tasks, monitoring and analyzing the performance of robots, maintenance and repair, and managing the human-robot interaction. By effectively managing the fleet of mobile robots, warehouses can increase efficiency, reduce costs and improve customer satisfaction. With the increasing use of mobile robots in warehouses, effective fleet management will be increasingly important in ensuring the smooth operation of the warehouse.

Key Challenges in Mobile Robot Fleet Management

The world of robotics, while awash with possibilities, is not without its challenges, especially when it comes to managing expansive fleets of mobile robots. As these fleets become integral to the operational fabric of industries, the complexities they introduce demand astute management and foresight. The task isn’t merely about ensuring that robots fulfill their designated roles but optimizing this performance in a dynamic, interconnected environment.

The ideal fleet management system is akin to a maestro, orchestrating a symphony of robotic movements, data flows, and human interactions. However, achieving this level of orchestration poses a myriad of challenges. From the intricate dance of coordination among robots, ensuring they move harmoniously, to the relentless demands of real-time data processing, each challenge brings its own nuances.

Add to this the ever-present need for scalability, the paramount importance of human safety, and the diverse environmental challenges robots face, and the gravity of the task becomes evident. Cost considerations, cybersecurity threats, and the imperative of seamless system integration add layers of complexity. In this section, we will navigate the labyrinthine landscape of these challenges, shedding light on their intricacies and exploring strategies to address them effectively.

- Complex Coordination: As robotic fleets expand, achieving harmonious coordination isn’t just about preventing collisions. It’s about synchronizing operations to extract the maximum efficiency from each robot. Consider, for example, a warehouse environment: Robots must predictively respond to the movements of their counterparts, ensuring that their operations align with the overarching productivity objectives, like optimizing pick-up and delivery routes or coordinating with automated storage systems.

- Real-time Data Processing: Beyond the primary data streams, such as sensor input and battery status, real-time processing now encompasses advanced analytics that can predict wear and tear, and even behavioral analytics that optimizes robot paths based on historical data. The sheer volume and complexity of this data require robust computational backbones to ensure that insights are generated as quickly as data is ingested.

- Communication: The dialogue between robots goes beyond simple task allocation. It’s about sharing environmental data, adapting to real-time changes, and even updating each other about potential hazards. In essence, each robot becomes a node in a vast, interconnected web, collectively working towards operational efficiency.

- Scalability: The evolutionary path of an organization’s needs demands that fleet management systems aren’t just scalable but are also adaptive. This means not only accommodating more robots but also incorporating newer robot models or technologies without overhauling the entire system.

- Safety Concerns: The proximity of robots to humans raises safety considerations beyond collision avoidance. These include ensuring that robots can predictively respond to human actions, have safety protocols in place for system failures, and can actively communicate their intentions to their human co-workers.

- Battery and Energy Management: Beyond just recharging, modern fleet systems must manage energy based on task priority, estimate battery degradation over time, and even route robots to energy stations optimally. This ensures that robots are always operational when most needed, and downtime is minimized.

- Environmental Adaptability: Robots must be resilient, navigating challenges from fluctuating temperatures to varying terrains. Advanced sensory systems allow them to adapt, whether it’s adjusting their speed on slippery surfaces or changing operational parameters based on ambient conditions.

- Cost Implications: Return on Investment (ROI) becomes central when deploying fleet management systems. Organizations aren’t just seeking systems; they’re looking for solutions that promise tangible returns, whether in the form of increased efficiency, reduced operational costs, or longer robot lifespan.

- Integration with Other Systems: Seamless integration is no longer a luxury; it’s a necessity. As robots interface with diverse systems, they should be able to pull and push data effortlessly. Whether it’s syncing with inventory databases to update stock levels or integrating with security systems for access control, the integration spectrum is broad and vital.

- Cybersecurity: Protecting against cyber threats is more than just encryption and firewalls. It’s about ensuring real-time threat detection, having recovery protocols in place, and constantly updating security measures to counter evolving cyber risks. As robots become data repositories and operational linchpins, their protection becomes paramount.

The future of mobile robot fleet management

The burgeoning world of mobile robotics stands on the cusp of a transformative era, with the management of robot fleets being at its epicenter. As we peer into the horizon, a confluence of technological breakthroughs and evolving industry needs paints a dynamic picture of the future of Mobile Robot Fleet Management.

This future is not merely a linear progression from the present but a quantum leap that promises to redefine the paradigms of automation, productivity, and collaborative functionality. We are progressing beyond the rudimentary automation stages, ushering in a new age where robots don’t just follow pre-defined protocols but adapt, learn, and integrate into broader organizational structures.

From leveraging the computational prowess of AI and ML to the promising vistas opened up by 5G, from human-robot synergies that promise to amalgamate the best of both worlds to harnessing AR and VR for immersive operational insights, the future beckons with unparalleled potential. Yet, as we tread this path, challenges around sustainability, cybersecurity, and customization loom large. This section delves deep into these upcoming trends, shedding light on the transformative journey ahead, and the myriad ways in which the industry is poised to evolve.

- Advanced Artificial Intelligence (AI) and Machine Learning (ML): AI and ML aren’t just buzzwords; they’re the bedrock of future fleet management. They will transcend basic functionalities, allowing robots to adapt to diverse environments and challenges. As robots encounter novel scenarios, they’ll adjust their behaviors based on previously gathered data, ensuring constant optimization of operations.

- 5G and Beyond: The importance of rapid and efficient communication cannot be overstated in fleet management. With the ushering in of technologies like 5G, robots will not only communicate faster but will transmit more complex data sets, paving the way for richer insights and more nuanced decision-making.

- Energy Innovations: As the demands on robot fleets increase, so will the need for sustainable energy sources. Advancements in battery longevity mean fewer interruptions and more productivity. Moreover, groundbreaking methods like wireless charging stations dotted within operational areas can facilitate continuous operations, fundamentally reshaping the dynamics of workflow.

- Human-Robot Collaboration: The collaboration between man and machine is poised to reach unparalleled synergy. Advanced sensing capabilities will allow robots to not only coexist but also cooperatively work alongside humans. This augments the potential for more complex tasks that require the dexterity of humans and the precision of robots.

- Augmented Reality (AR) and Virtual Reality (VR): AR and VR hold promise far beyond entertainment. For fleet managers, these technologies can visualize complex robotic operations, offering insights into workflows, identifying bottlenecks, and simulating potential changes before implementing them, leading to more informed decisions.

- Holistic Integration: The silos within organizations are set to dissolve. Future robot fleet management systems will converse seamlessly with other enterprise applications. This integrated approach will ensure streamlined operations, harmonized data flow, and optimized resource allocation across departments.

- Predictive Maintenance: Proactivity will replace reactivity. Leveraging AI-driven analytics, management systems will preemptively identify wear and tear, ensuring timely interventions. Such anticipatory maintenance reduces sudden breakdowns, ensuring continuity and longevity of robotic assets.

- Customizability: The one-size-fits-all approach will become obsolete. As organizations diversify their operations, fleet management solutions will need to be tailorable. Customizable dashboards, alerts, and operational protocols will ensure that different industries, and even individual organizations, can mold the systems to reflect their unique needs.

- Cybersecurity Advancements: As fleet management systems become more interconnected, they also become more vulnerable. Thus, the future will see an emphasis on robust cybersecurity measures, incorporating advanced encryption, real-time threat detection, and rapid response mechanisms to safeguard sensitive data and ensure uninterrupted operations.

- Sustainability: Environmental stewardship will be a cornerstone of the next-gen robot fleet management ethos. This commitment will manifest in multiple ways – from crafting robots using sustainable materials to devising energy-efficient paths and tasks. With a focus on reducing carbon footprints, fleet management will actively contribute to a greener planet.

Mobile robot fleet management is evolving at a rapid pace, driven by technological advancements and the increasing adoption of robots in various sectors. While there are challenges in ensuring the efficient management of these robot fleets, the future holds immense potential. As AI, connectivity options, and other technologies advance, managing large fleets of robots will become more streamlined and efficient. Organizations that adopt these advancements early will be better positioned to derive maximum value from their robot fleets, ensuring operational efficiency and a competitive edge in their respective domains.

How Vecna Robotics fleet management software supports your fleet

Vecna Robotics’ PivotalTM software is tuned to optimize the efficiency of the AMR fleet within your facility to ensure maximum throughput, work coordination and safety. Read more information about our award-winning PivotalTM software here, or contact us today to schedule a consultation with a factory automation expert.