What is cross docking?

Cross docking is a logistics method in which goods are transferred directly from an incoming transportation vehicle to an outgoing transportation vehicle with minimal handling and storage in between. The goal of cross docking is to reduce handling and storage costs, as well as improve the efficiency and speed of the supply chain. Automation can help with cross docking by streamlining and simplifying the process, reducing human error, and increasing the speed and accuracy of the transfer of goods.

One of the key components of cross docking is the use of a cross docking facility, which is a warehouse or distribution center specifically designed for this purpose. These facilities typically have a large receiving area for incoming goods and a separate area for outgoing goods, with an empty area in between for the transfer of goods. The receiving area is where goods are received from incoming transportation vehicles and sorted and consolidated for transfer to outgoing transportation vehicles. The outgoing area is where goods are loaded onto outgoing transportation vehicles for delivery to their final destination.

Maximizing efficiency of cross docking

Automation can be used throughout the cross docking process to improve efficiency and reduce costs. For example, automated systems can be used to sort and consolidate incoming goods, which can greatly speed up the process and reduce the need for manual labor. Automated systems can also be used to load and unload goods from transportation vehicles, which can greatly reduce the risk of damage or loss of goods. Additionally, automated systems can be used to track and monitor the movement of goods throughout the cross docking facility, which can help to ensure that the right goods are being sent to the right destination in a timely manner.

4 ways automation improves cross docking

- One way that automation can help with cross docking is through the use of conveyor-based sorters. These systems use a complex system of overhead conveyor belts, scanners, sorters, and other automated equipment to move individual packages directly from the back of an inbound trailer to being loaded onto an outgoing trailer with minimal human touches. This can greatly speed up the process and reduce the need for manual labor. Additionally, automated systems can be used to sort and consolidate incoming goods, which can greatly speed up the process and reduce the need for manual labor. Automated systems can also be used to load and unload goods from transportation vehicles, which can greatly reduce the risk of damage or loss of goods.

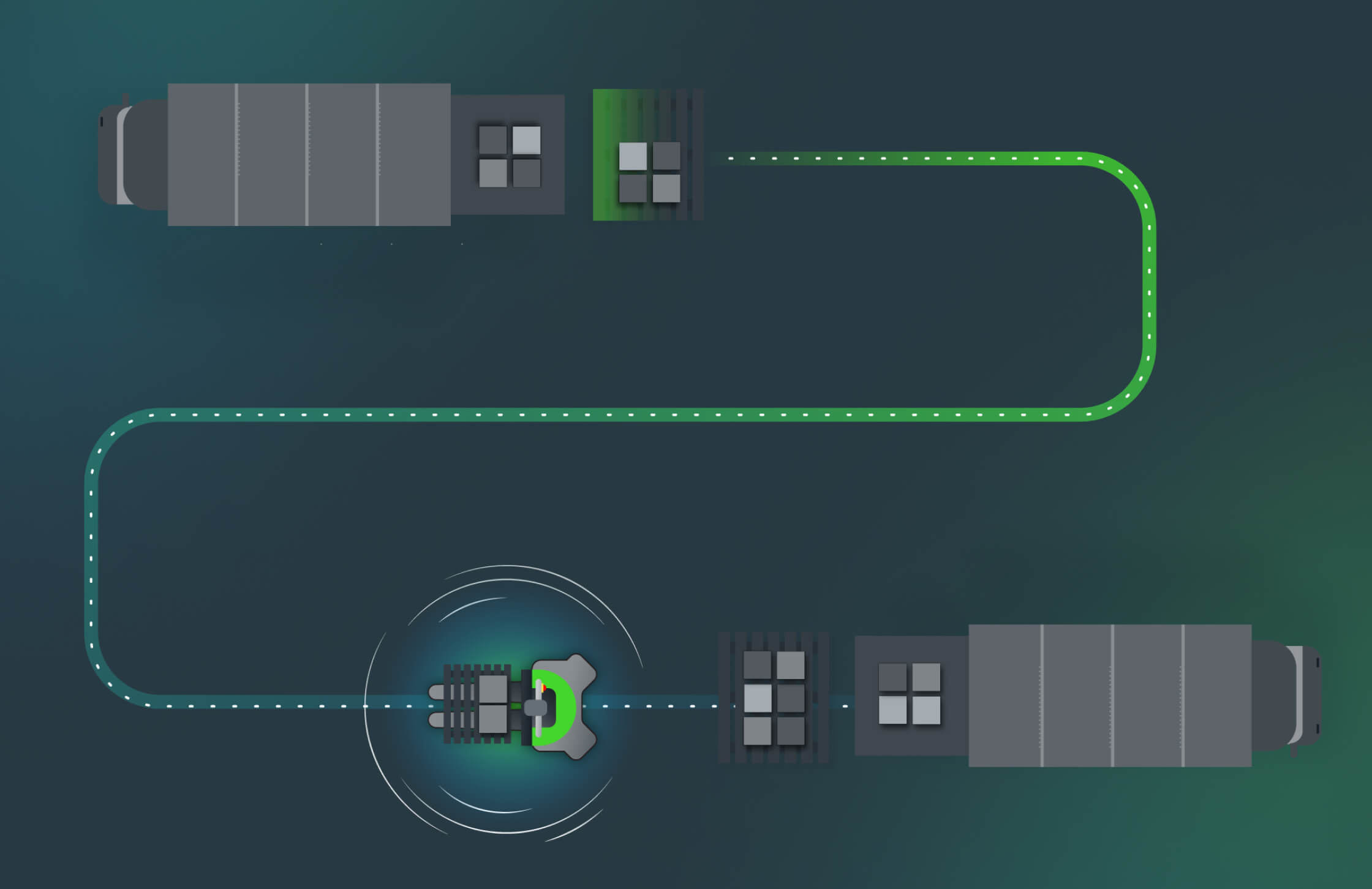

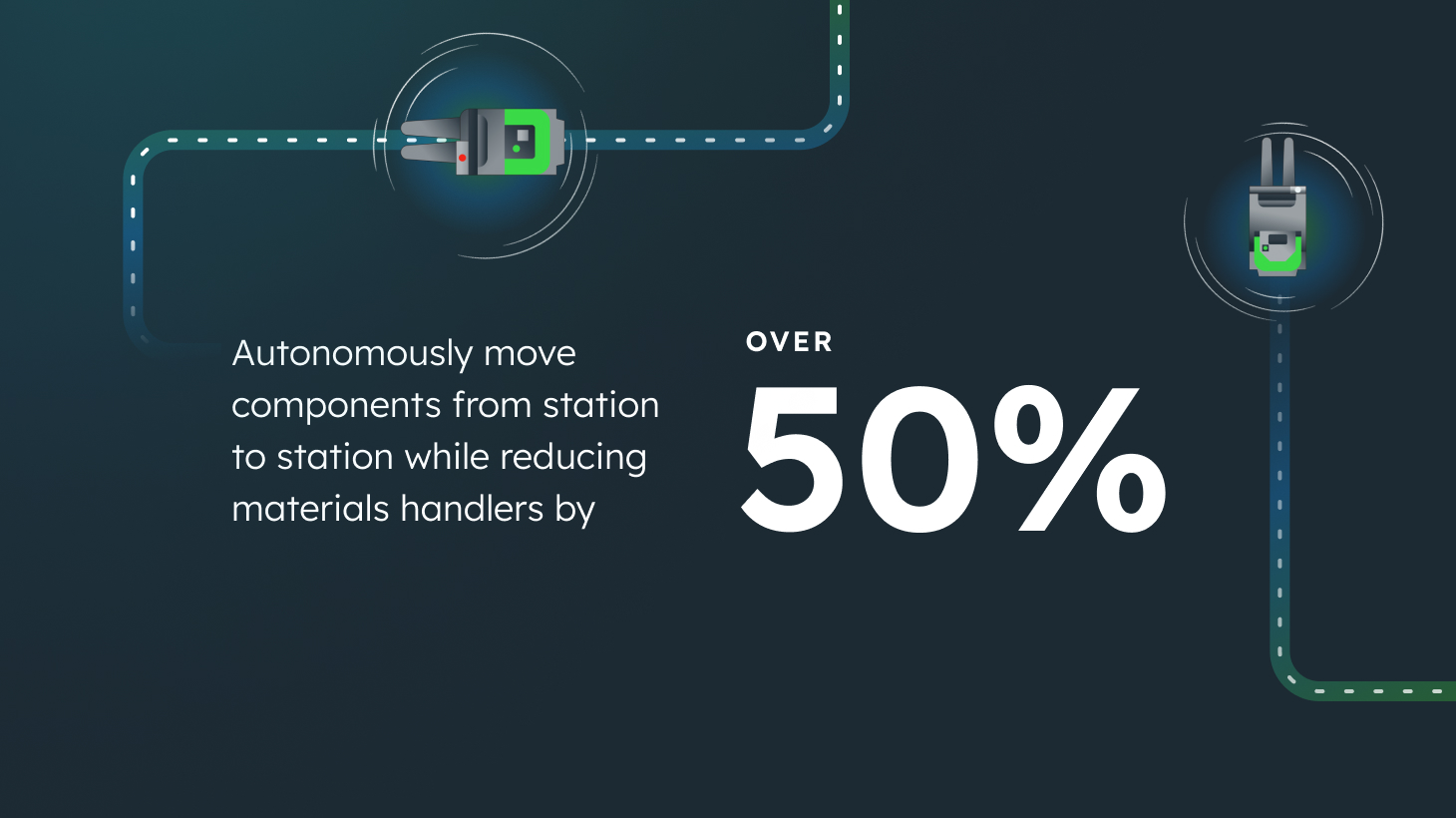

- Autonomous mobile robots (AMRs) are increasingly being used in cross docking operations to automate the movement and sorting of goods, as well. In a cross docking operation, AMRs can be used to bring incoming goods from receiving docks to the sorting area, where they are then directed to their final destination for shipping. This can help to reduce the amount of manual labor required, as well as improve accuracy and speed of sorting and transportation. AMRs can also be used in coordination with other warehouse automation technologies such as conveyors, and warehouse management software to optimize the entire process.

- Another way that automation can help with cross docking is through the use of computer-aided transportation management systems (CATMS). These systems are used to track and monitor the movement of goods throughout the cross docking facility and to coordinate the transfer of goods from incoming to outgoing transportation vehicles. This can help to ensure that the right goods are being sent to the right destination in a timely manner, and can also help to reduce the risk of damage or loss of goods.

- Automation can also help with cross docking by improving communication and coordination between the different parties involved in the supply chain. For example, automated systems can be used to provide real-time updates on the status of goods as they move through the cross docking facility, which can help to ensure that everyone involved in the supply chain is aware of any potential delays or issues. Additionally, automation can be used to automate the process of creating and updating shipping documents, which can help to ensure that the right goods are being sent to the right destination in a timely manner.

In summary, cross docking is a logistics method in which goods are transferred directly from an incoming transportation vehicle to an outgoing transportation vehicle with minimal handling and storage in between. Automation can help with cross docking by streamlining and simplifying the process, reducing human error, and increasing the speed and accuracy of the transfer of goods. Conveyor-based sorters, AMRs, and computer-aided transportation management systems are a few examples of how automation can be used to improve the cross docking process. Additionally, automation can also help to improve communication and coordination between the different parties involved in the supply chain.

Cross docking robotics solutions

Fortunately, Vecna Robotics has solutions like our Autonomous Forklift, Autonomous Tugger and Co-bot Pallet Jack that are tailor-made for automating cross docking operations. For more information about how you can get started with your cross docking automation journey, go to our From No Bot to Robot page, or you can contact us today to schedule a consultation with a warehouse automation expert.