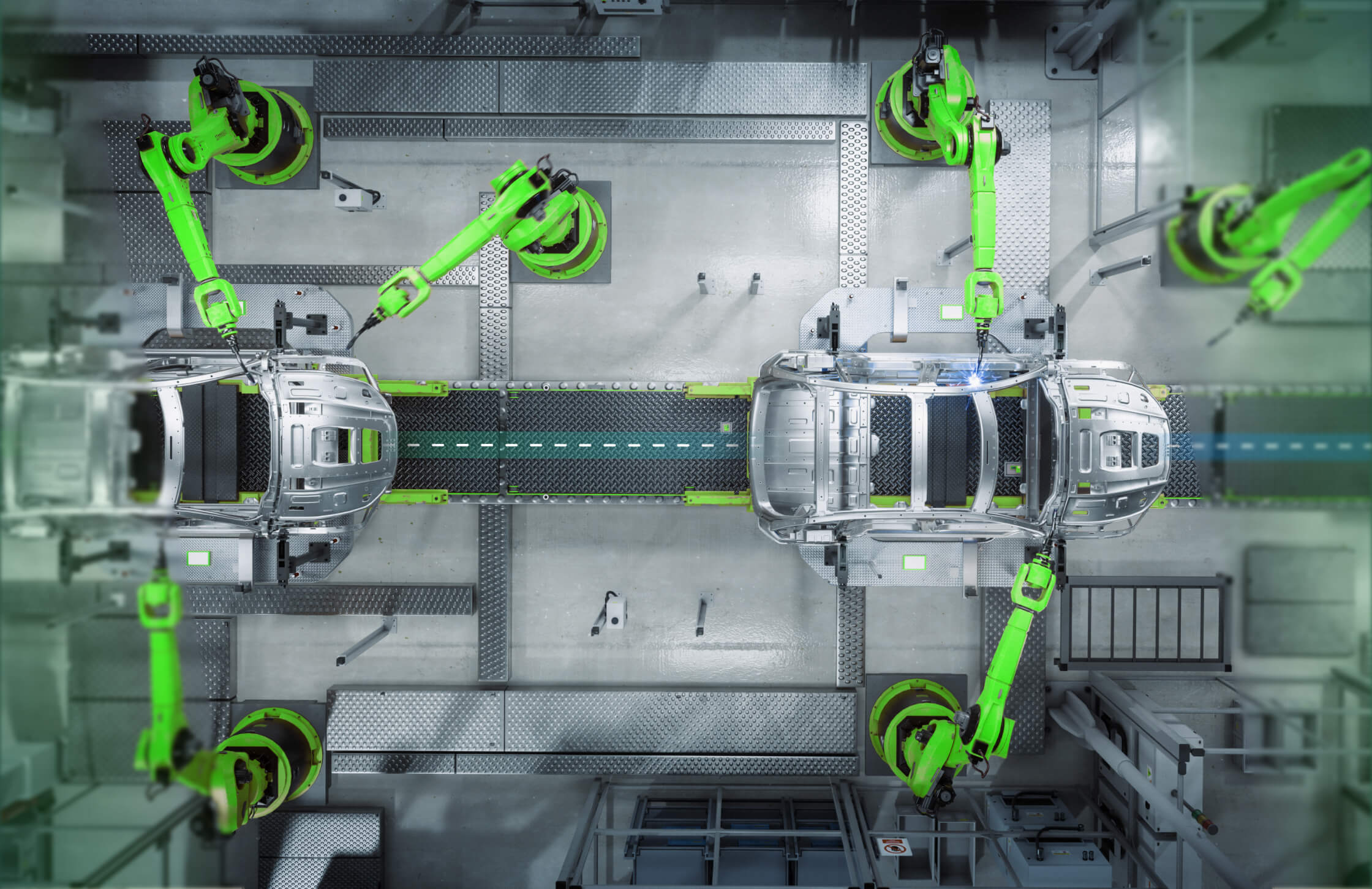

Small manufacturers are looking at automated fork truck alternatives, and more companies are investing in AGVs or the improved technology of AMRs to improve plant-floor efficiency and reduce operating cost. As this flexible technology is now more affordable and easier to use on assembly lines, many smaller manufacturers and single location distribution centers are deploying driverless carts, robotic parts bins, and autonomous tuggers. Manufacturing engineers have best-practice lean manufacturing solutions which are driving prices down making these solutions available to everyone.

According to MHI, automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) are defined as driverless vehicles that consist of one or more computer-controlled, wheel-based load carriers.

Engineers can choose between autonomous tuggers that pull a string of carts or trailers in a train; self-driving unit load carriers that move subassemblies and work-in-process from one assembly station to another; or other vehicles that interface with pickup and drop-off points on the plant floor. All of these options are available with autonomous capabilities – as AMRs are smaller, cheaper, and easier to install than traditional AGVs. Tugger robots are popular for applications where lighter loads and flexibility are required in manufacturing.

Fork Truck Alternatives: AGVs vs. AMRs

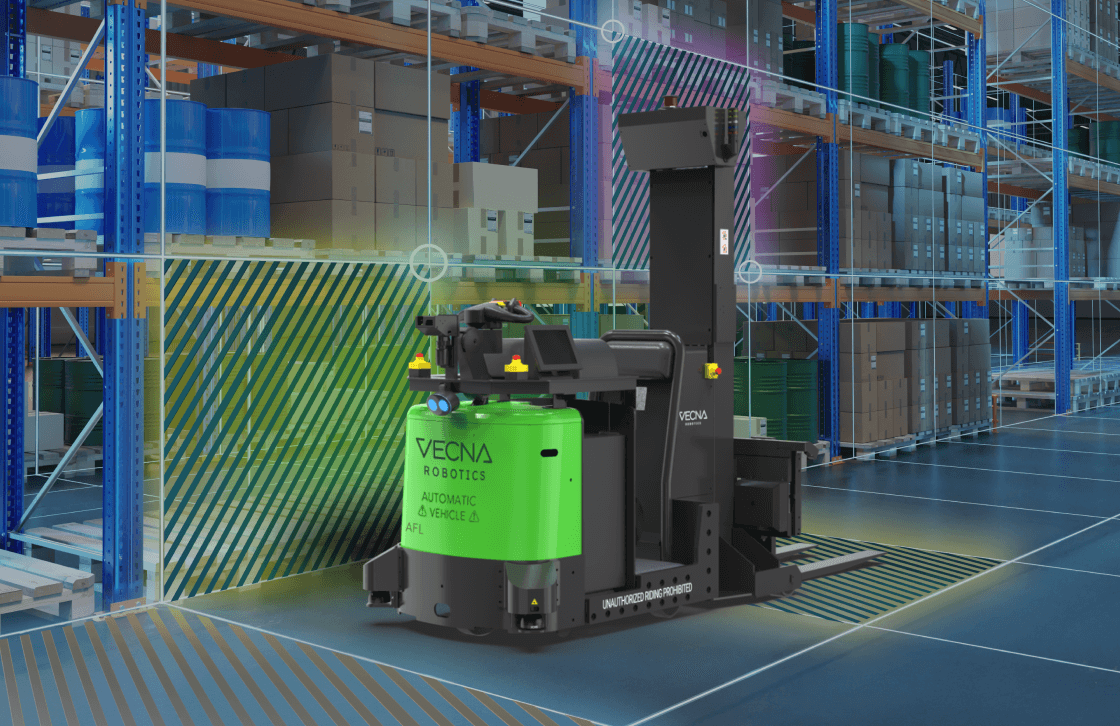

Due to the high cost of entry, automated guided vehicles (AGVs) were only found in warehouses, automotive assembly plants, and other operations with large amounts of floor space. With the help of Vecna Robotics, recent advancements in AMR technology has made automated fork truck alternatives like tuggers more appealing to small and mid-sized manufacturers in a wide variety of industries.

Today’s AMRs are more advanced than the AGVs available a decade ago. The machines are now faster, safer, easier to program, more precise and less expensive. According to John Hayes, AMR expert, “Vecna Robotics is leading AMR development focusing on software and safety systems. Better throughput, productivity, and cost-effective technology are now available to even the smallest manufacturer or distributor who have been ignored for far too long.”

While AGVs and AMRs perform similar tasks, there is a large variance in their methods and in the capabilities that stem from them. Both, as a baseline function, are able to transport materials through industrial facilities and effectively reduce the need for manually operated machinery. However, the efficiency gains generated will depend on the distinct abilities of your robot’s competencies in navigating your facility and accomplishing its tasks in a dynamic environment. Understanding the varying abilities of AGVs and AMRs in path-planning and navigating will help guide those automating toward the best investment.

With e-commerce exploding and customer expectations on the rise, distribution and fulfillment centers as well as third-party logistics (3PLs) providers need an innovative way to reduce costs and increase throughput. Vecna Robotics provides a complete range of low-infrastructure solutions to automate material handling needs. All systems are safety certified to operate alongside people and can accommodate the operational model that achieves the best efficiency today with unmatched flexibility for tomorrow.