Automation Workflows That Go Beyond Movement

Vecna Robotics empowers operations to move smarter. Our intelligent automation systems tackle some of the most complex workflows in warehousing and manufacturing—enhancing speed, safety, and scalability at every turn.

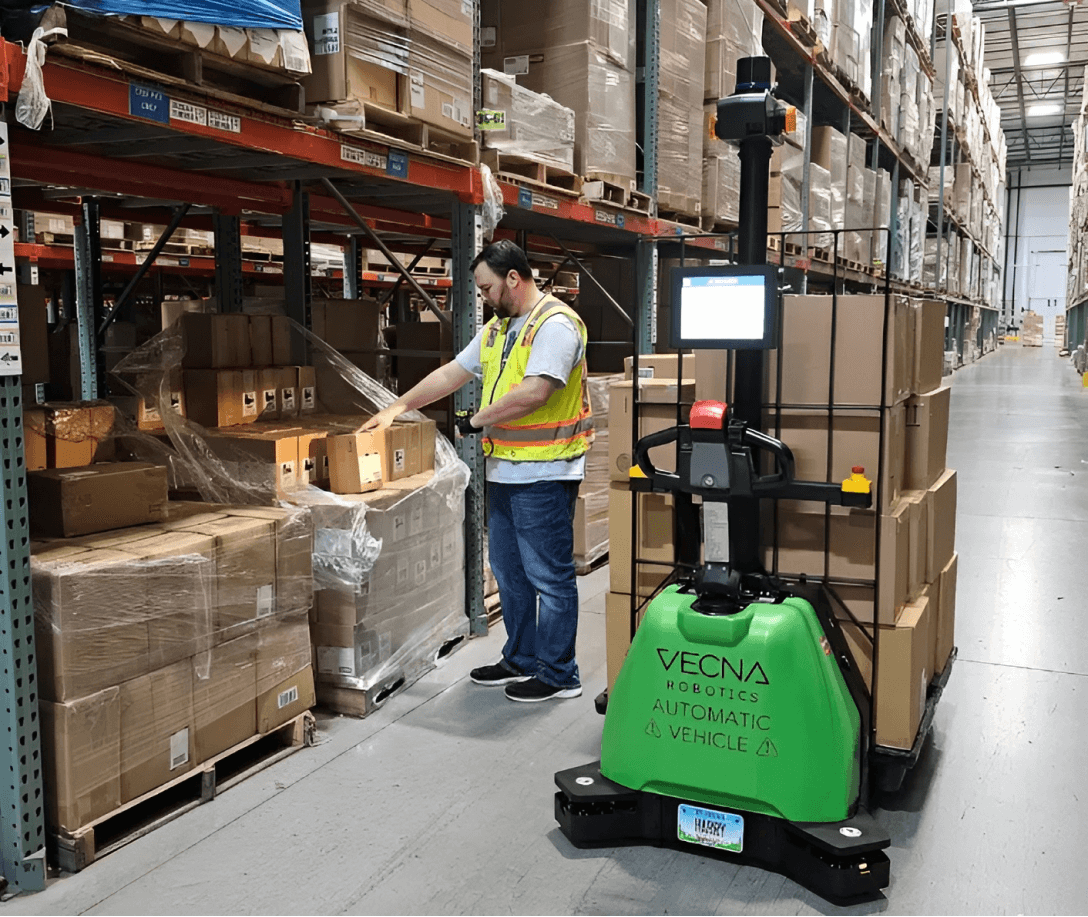

Smarter picking. Higher throughput.

Case Picking

Case picking is one of the most labor-intensive and travel-heavy workflows in the warehouse. Vecna’s automation streamlines it by orchestrating picker-robot collaboration that boosts accuracy, reduces fatigue, and dramatically cuts walking time.

See how it works

-

Vecna Orchestration Engine receives picklists from your WMS and intelligently optimizes order release.

-

CPJs begin by picking up an empty pallet from the designated staging area and gets a fresh battery, as required.

-

CPJs visit all pick stops on the pick list, following an optimized route that minimizes travel time and avoids congestion.

-

Wearable UIs tell associates exactly where to go to meet the next CPJ, which cases to load, and what to scan.

-

CPJs wait at pick stop as associate completes the pick, and navigates autonomously to its next stop.

-

Full pallets are dropped off to the stretch wrapper or outbound dock.

See how it works

-

Vecna’s system is given a pickup mission to clear pallets from the receiving dock and dispatches an AMR.

-

The AMR autonomously picks the first pallet and plots the most efficient route to it’s P&D location.

-

The AMR drops the pallet at end-of-aisle staging and a manual operator completes final putaway into the rack location.

-

A manual operator picks an outbound pallet and drops at endcap staging for Vecna.

-

The system dispatches an AMR to transport the outbound pallet from end-of-aisle staging to the shipping dock.

Make your cross-dock cross-functional.

Cross Docking

Tap into the power of route-free navigation and keep your dock-to-dock transportation running like clockwork. Vecna’s flexible navigation allows many robots to move many goods, to many locations safely and quickly.

Robot used in this workflow:

FORKLIFT

See how it works

-

Vecna’s system is given a pickup mission to clear pallets from the receiving doc and dispatches an AMR.

-

The AMR autonomously picks the first pallet and plots the most efficient route to its P&D location, avoiding obstacles along the way.

-

The AMR drops the pallet to the appropriate outbound staging lane for final shipping.

Keep Your Lines Moving

Line-Side Delivery

Ensure your production lines never miss a beat. Vecna Robotics’ AMRs streamline the delivery of parts and materials directly to the line — reducing wait time, minimizing inventory buildup, and eliminating manual material runs. By autonomously transporting pallets, bins, or carts from storage or receiving areas to line-side staging, our autonomous forklift, tugger or pallet jack can help manufacturers maintain continuous flow and respond dynamically to production demands.

Robots used in this workflow:

FORKLIFT | TUGGER | COBOT PALLET JACK

See how it works

-

Operators or WMS systems trigger a line-side delivery task for required parts or materials — based on production schedules, low-inventory alerts, or takt-time thresholds.

-

The autonomous tugger, forklift or pallet jack receives the task via Vecna’s Pivotal orchestration system and navigates from the parts or supermarket area to retrieve the specified item or cart.

-

The AMR navigates safely and efficiently through the facility, avoiding obstacles and prioritizing high-traffic work zones to deliver on time.

-

Materials are delivered directly to the designated line-side location with pinpoint accuracy, enabling operators to keep production moving without interruption.

-

The vehicle either returns the empty container or receives its next assignment — maximizing utilization with minimal idle time.

Streamline the final leg.

End-of-Line

Fully automate the last steps of your operation. Vecna provides you with optimal delivery times by balancing takt times and demand loads via intelligent fleet orchestration.

Robots used in this workflow:

FORKLIFT | TUGGER | COBOT PALLET JACK

See how it works

-

After receiving a pickup call an AMR dispatches to the location and autonomously picks up the payload.

-

The AMR then travels and drops the payload at packaging.

-

The system notifies an AMR to pick up the fully packaged payload and deliver it to the appropriate outbound staging lane.

Flow through production with fewer slowdowns.

Work in Progress

Autonomously move components from station to station while reducing materials handlers by over 50%. Vecna cuts traffic while improving safety and productivity with dynamic routing that optimizes routes and drop off locations based on real-time availability.

See how it works

-

The Vecna system receives a pickup mission from an operator and dispatches an AMR.

-

Once the payload has been secured, the AMR autonomously selects the best route and navigates to the next available workcell.

-

The system updates, and the AMR process to the next mission.

Small tasks. Big impact.

Point-to-Point

Not every workflow is a bulk move. Automate in-between workflows and boost productivity by 40%. Free your workers from boring, laborious, but essential tasks. While other solutions ignore these low-volume jobs, Vecna’s automation drastically reduces the drain these non-value-add moves place on your resources.

Robots used in this workflow:

FORKLIFT | COBOT PALLET JACK

See how it works

-

An operator calls for a robot to be sent to their location for a pickup.

-

Vecna’s system dispatches a CPJ AMR to the pickup location.

-

The operator manually spears the payload and programs the CPJ with its drop-off destination.

-

The CPJ navigates to the programmed destination and autonomously drops off the pallet.

Let’s go

Automate your key ground-to-ground workflows right now

Thank you for getting in touch

We aim to respond to all messages within 1-2 business days.

In the meantime you might be interested in some of these resources.