Pulls a ton, or three

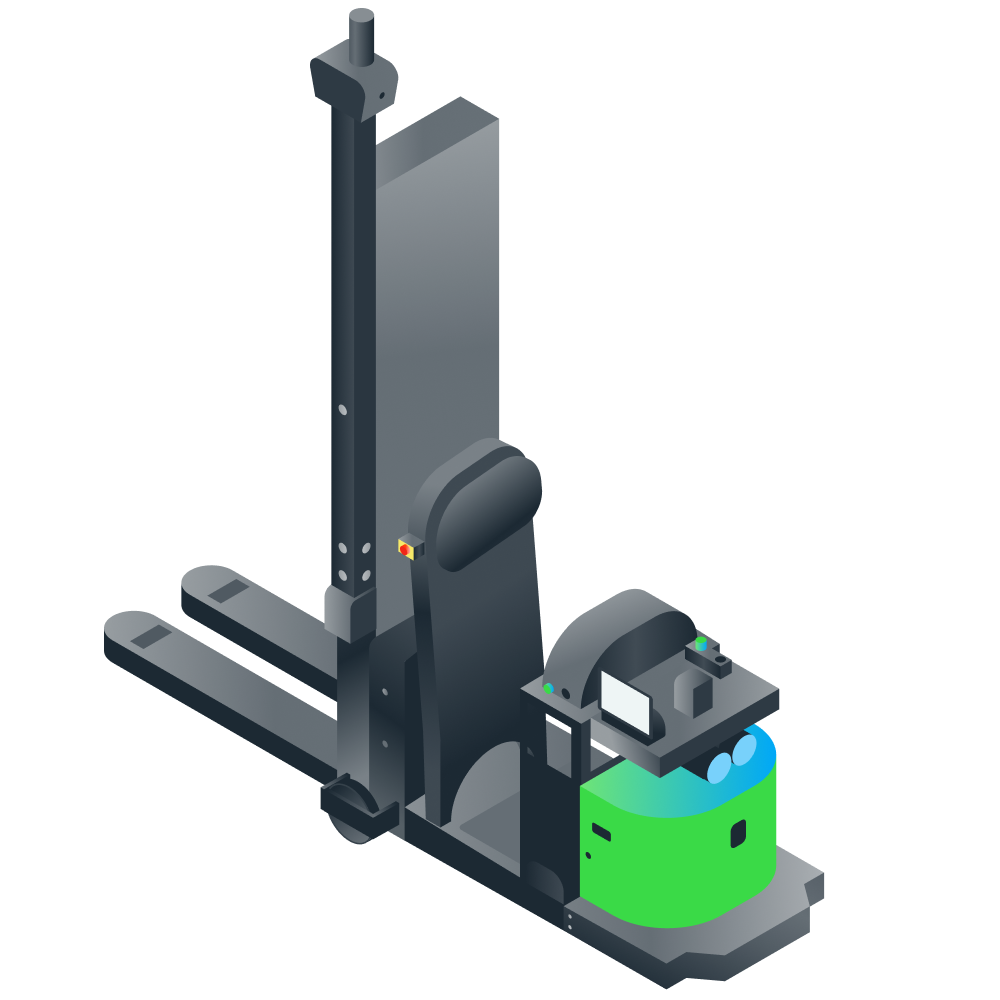

Vecna APT Autonomous Pallet Truck

In it for the long haul

From retail distribution centers to grocery case pick facilities, the Vecna APT autonomous pallet truck is the long haul superstar you’ve been looking for.

About Vecna APT

This robot does the dirty work while your operators do the human work

With Vecna APT driverless pallet truck, cut out non-value add long-distance travel and improve efficiency for lift operators – all without compromising capacity.

7936 lbs max payload

Blazing fast

6.7 mph top speed

Clean hand off

18’6 ft right angle stack

Squeezes through

8’6 ft aisle width

Features and Functionality

Power up your warehousing and distribution facilities

Advanced Pallet Handling

Handles stringer, block, plastic pallets, with or without bottom boards

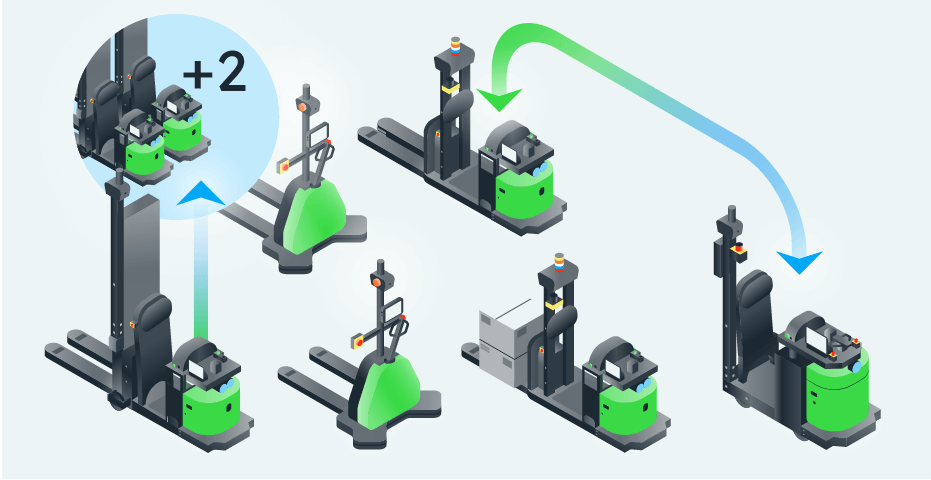

Flexible Configurations

Takes on staging lanes, drop zones, individual spots, FIFO, and more

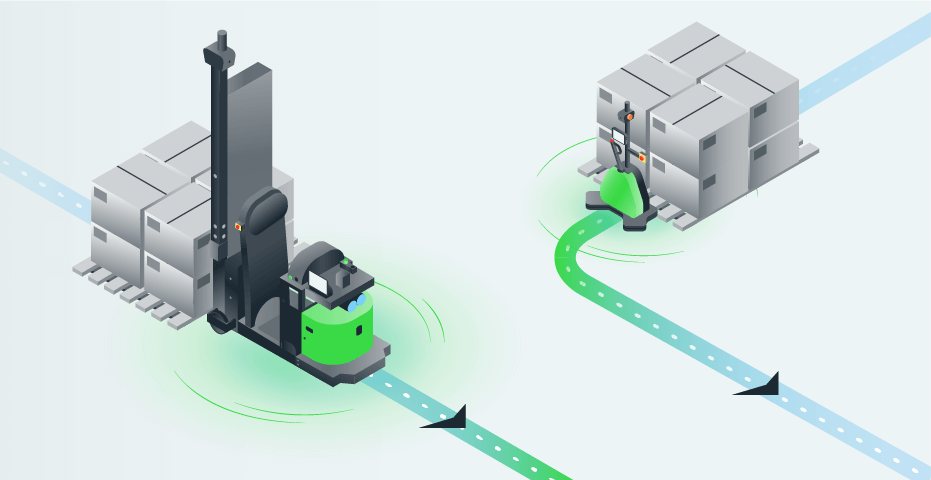

Dynamic Route Planning

Utilizes dynamic traffic management for load balancing

Multi-Pallet Hauling

Takes on double-stacked pallets up to 8,000 lbs

LPN Scanning

Scans pallet barcodes and sends updates to your WMS

Opportunistic Charging

Runs 24/7 using opportunistic charging

ANSI B56.5 Compliant

Keeps your employees, equipment and goods safe.

Task Interleaving

Replans missions in real-time to optimize forks-full efficiency

Optimize your warehouse workflows

Trusted by industry leaders

and those in the know

Let’s go

Optimize your critical workflows right now

Have questions about what Vecna can do for you? Tell us about yourself and an automation expert will be in touch shortly.

Thank you for getting in touch

We aim to respond to all messages within 1-2 business days.

In the meantime you might be interested in some of these resources.

Frequently asked questions

How does the Vecna APT autonomously navigate my facility?

During initial setup, the Vecna APT creates a virtual map of your facility with its on-board sensors based on permanent infrastructure. Once this map is created, routes, destinations, and traffic rules can be flexibly programmed into the map without requiring any facility changes, and automatically syncs across the entire fleet. Based on this map, the Vecna APT will then automatically connect all potential routes/destinations together, and – similar to a human driver – will plan the most efficient route from A to B in real-time, including updating its plan/re-rerouting as needed.

What types of pallets can the Vecna APT handle?

The Vecna APT can handle various pallet types, including stringer, block, and plastic pallets, with or without bottom boards.

What staging area configurations can the Vecna APT handle?

The Vecna APT is flexible to different warehouse setups and can handle dock staging lanes, multi-pallet drop areas, discrete P&D spots, First-In-First-Out (FIFO) buffer zones, and other common pallet staging configurations.

What is the maximum payload capacity of the Vecna APT?

The Vecna APT can handle a maximum payload of 7936 lbs, making it suitable for handling heavy loads.

What is the top speed of the Vecna APT?

The Vecna APT can reach a top speed of 6.7 mph, ensuring fast and efficient pallet transportation.

How wide of an aisle can the Vecna APT navigate through?

The Vecna APT can navigate through spaces as narrow as 6 ft. We recommend aisle widths of at least 9 ft to allow the APT to travel at speed.

What is the right-angle stack capability of the Vecna APT?

The Vecna APT requires 18.5 ft of space to execute a 90-degree turn.

Can the Vecna APT haul multiple pallets simultaneously?

Yes, the Vecna APT is capable of hauling double-stacked pallets up to 8,000 lbs, improving productivity in material transportation tasks.

Does the Vecna APT support LPN scanning and integration with Warehouse Management Systems (WMS)?

Yes, the Vecna APT is equipped with LPN scanning capabilities, enabling pallet barcode scanning and seamless updates to your Warehouse Management System (WMS).

How does the Vecna APT ensure safe operation?

The Vecna APT complies with ANSI B56.5 safety standards, prioritizing employee safety, equipment protection, and goods security during its operation.

Discover a better way to go.

Robots as a service

Go with a solution that grows with you

Get the tech you need, when you need it without a huge, upfront capital expense and ongoing maintenance costs.