Material Handling Automation for

Automotive

33%

throughput improvement vs. manual operations

1.5x

more pallets moved per $ vs. manual MHE

2x

faster ROI vs. traditional AGV

99.9%

uptime with Pivotal™ autonomy and remote monitoring

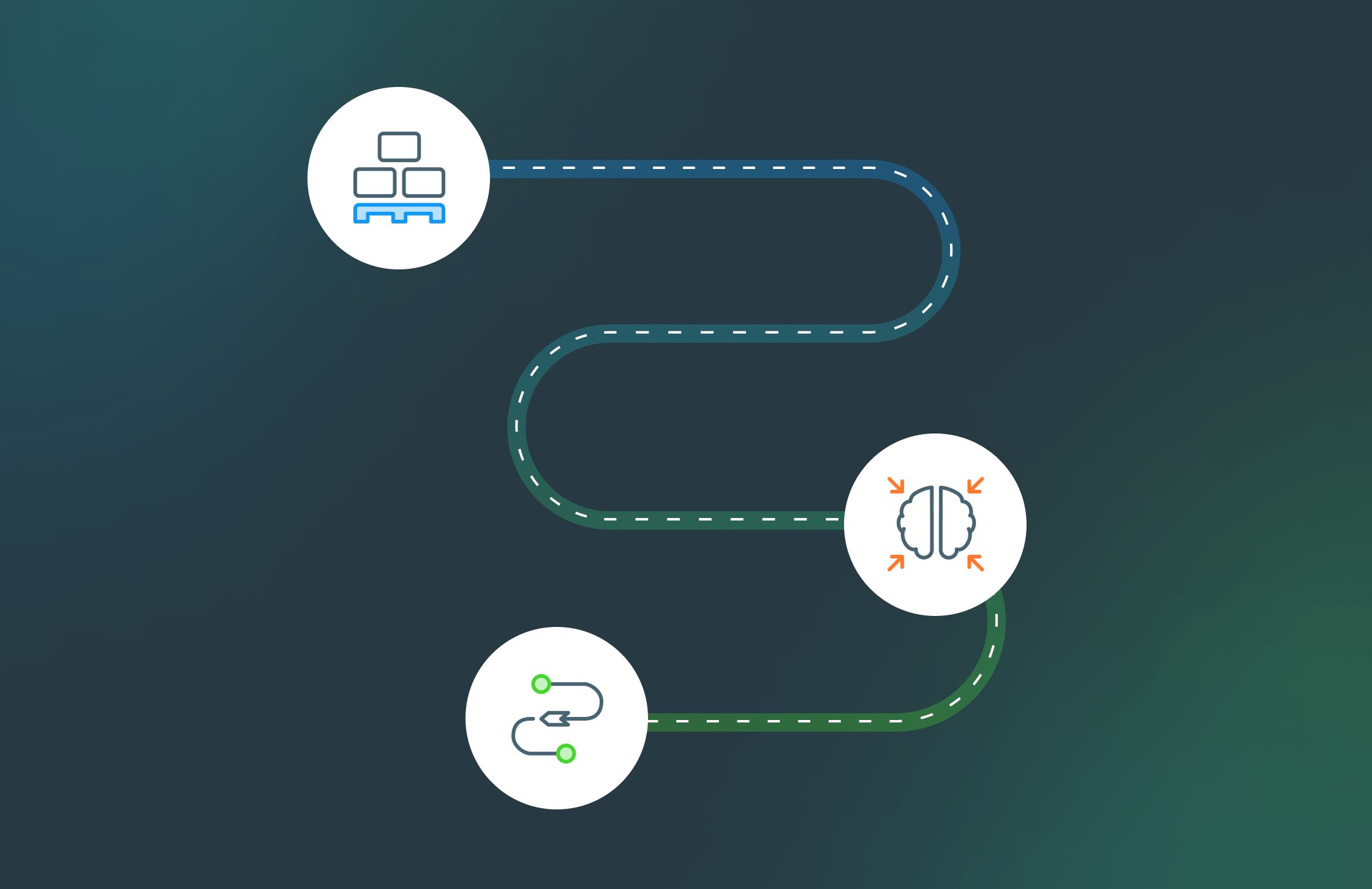

Deliver performance that scales with production demands.

In automotive manufacturing and logistics, every second counts. From just-in-time delivery of high-value parts to the precise sequencing of components on the assembly line, operational flow must be flawless. Vecna Robotics helps automotive operations go beyond basic automation—bringing intelligent orchestration, adaptable AMRs, and workflow-level visibility to every stage of production and material handling.

Why top automotive organizations choose Vecna Robotics

Just-in-Time Reliability

Deliver the right part, to the right place, at the right moment—every time.

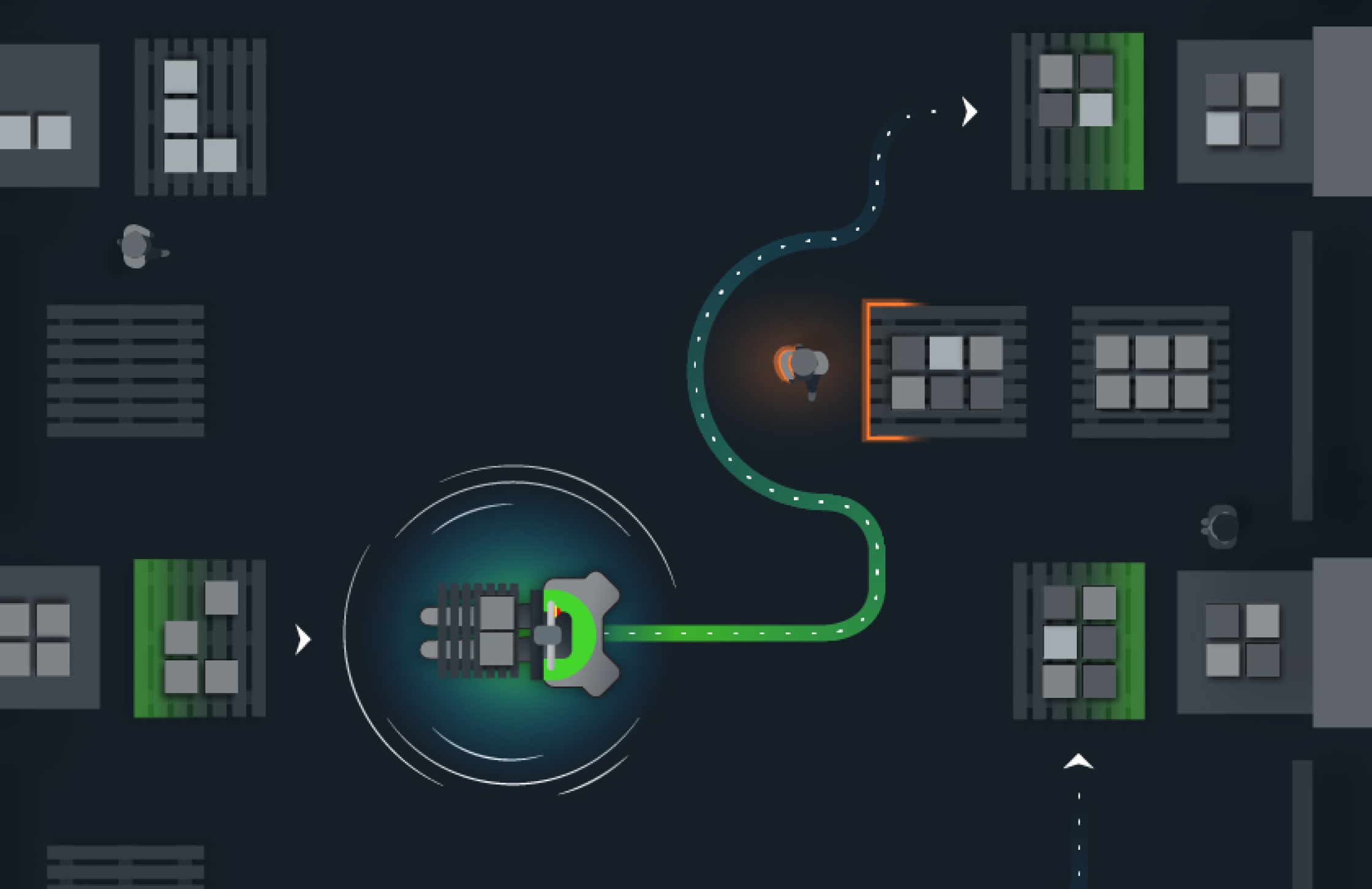

Orchestration for Complexity

Synchronizing the full flow of work between people, robots, and systems.

24/7 Support

99% uptime with remote monitoring and assistance.

Long-term partners

Earned confidence through years of delivering real-world results.

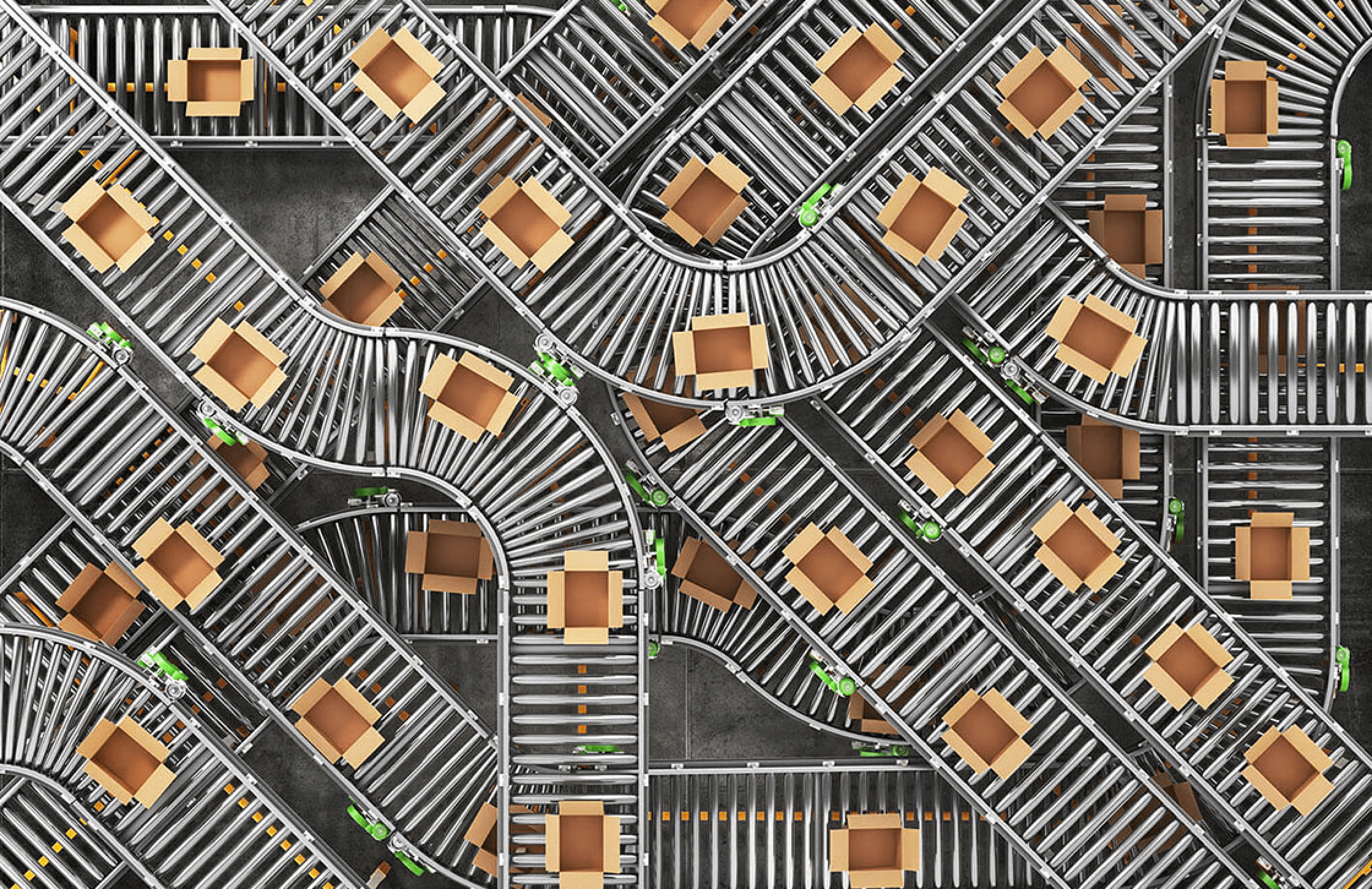

Streamline the final leg.

End-of-Line

Fully automate the last steps of your operation. Vecna provides you with optimal delivery times by balancing takt times and demand loads via intelligent fleet orchestration.

Robots used in this workflow:

FORKLIFT | TUGGER | COBOT PALLET JACK

Keep Your Lines Moving

Line-Side Delivery

Ensure your production lines never miss a beat. Vecna Robotics’ AMRs streamline the delivery of parts and materials directly to the line — reducing wait time, minimizing inventory buildup, and eliminating manual material runs. By autonomously transporting pallets, bins, or carts from storage or receiving areas to line-side staging, our autonomous forklift, tugger or pallet jack can help manufacturers maintain continuous flow and respond dynamically to production demands.

Robots used in this workflow:

FORKLIFT | TUGGER | COBOT PALLET JACK

Flow through production with fewer slowdowns.

Work in Progress

Autonomously move components from station to station while reducing materials handlers by over 50%. Vecna cuts traffic while improving safety and productivity with dynamic routing that optimizes routes and drop off locations based on real-time availability.

Small tasks. Big impact.

Point-to-Point

Not every workflow is a bulk move. Automate in-between workflows and boost productivity by 40%. Free your workers from boring, laborious, but essential tasks. While other solutions ignore these low-volume jobs, Vecna’s automation drastically reduces the drain these non-value-add moves place on your resources.

Robots used in this workflow:

FORKLIFT | COBOT PALLET JACK

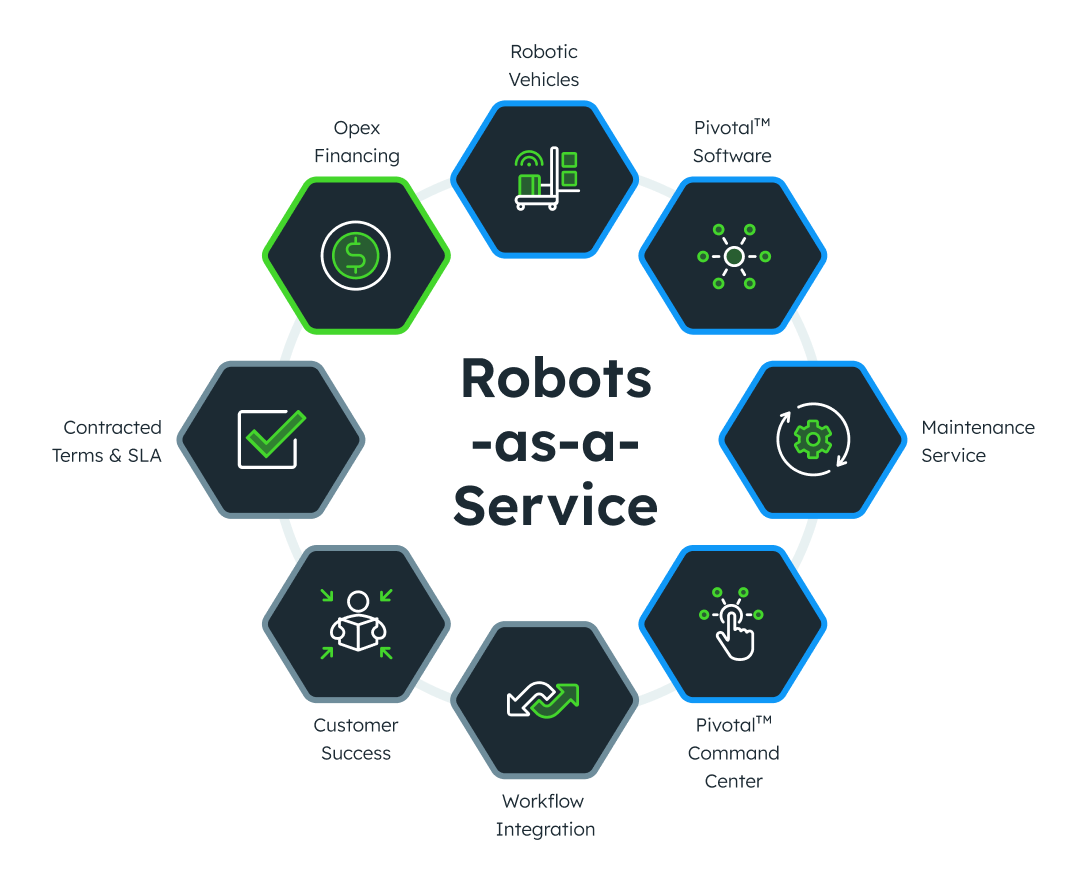

Robots as a Service

With competitive pricing tailored towards automotive operating budgets, Vecna’s solutions provide low-risk access to automation at a rapid ROI.

Trusted by industry leaders

and those in the know

Talk with our Automotive Industry Manager Today.

Discuss how you can unlock unparalleled efficiency with Vecna solutions—crafted for the unique demands of automotive.